- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

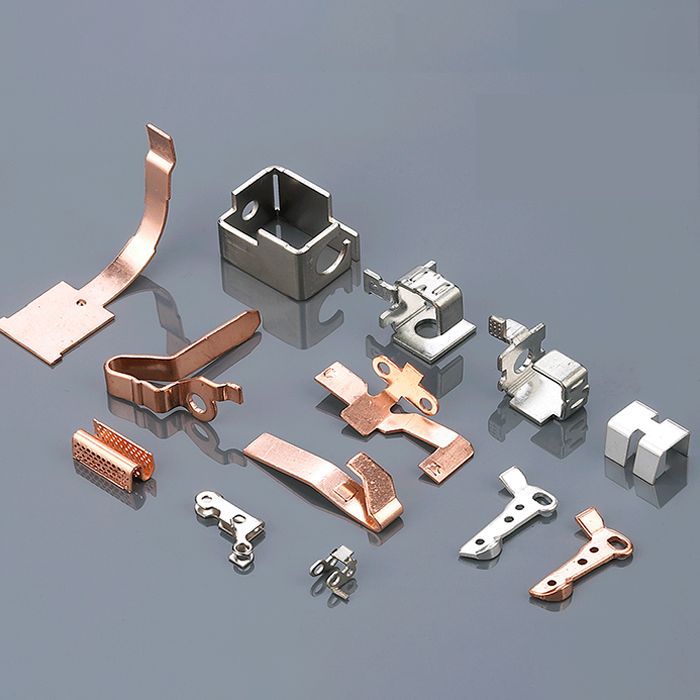

China bronze screws for boat building Manufacturers, Suppliers, Factory

"Based on domestic market and expand abroad business" is our enhancement strategy for bronze screws for boat building,drywall anchors heavy duty,screw in wall ties,camo fasteners,Fasteners, In our efforts, we already have many shops in China and our products have won praise from customers worldwide. Welcome new and old customers to contact us for the future long term business relationships.

bronze screws for boat building, We are going to do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

Hot Products

Metal Stamping Industry Springs

Metal Stamping Industry Springs have been used as an important part of many areas of modern life. Industrial springs produced by HY are affordable. Therefore, designing springs with available diversity has become critical for both commercial products and industrial applications.Stamping Photovoltaic Junction Box

HY is a factory that specializes in customizing and Stamping Photovoltaic Junction Box.The photovoltaic junction box is an important part of the solar panel. The junction box is the housing on the module where the PV strings are electrically connected. Solar panel junction box. Most junction box manufacturers are currently located in China.Die Casting Lower Cover

HY is a manufacturer and supplier of cast lower covers, using presses from 25 tons to 400 tons, and can meet customer needs whether it is precision or large Die Casting Lower Cover.Crimp Connectors

Xiamen Hongyu Intelligent Technology Co., Ltd. supports the customization of standard/non-standard parts of Crimp Connectors, and has more than 17 years of professional technology in hardware mold design and stamping product production. The minimum processing thickness of Crimp Connectors can reach 0.08mm, with excellent craftsmanship and no burrs.

Hongyu's advantages:

1. The selected materials far exceed the national standards

2. The service life of Stamping hardware terminals can reach more than 100,000 times

3. The durability of Crimp Connectors can reach more than 20,000 plug-in and pull-out times

4. Anti-oxidation/anti-fatigue/good rigidity/high precisionCheck Valve

Xiamen Hongyu Intelligent Technology Co., Ltd. has more than 17 years of processing and production experience, and has rich experience in the design and manufacture of various types of Check Valves and valve drive devices. HY's main products include: nuclear power valves, power station valves, fire water supply valves, chemical valves, petroleum valves, etc.

Type: Check Valve, 3 flanged check valve, swing check valve

Material: Stainless steel

Working pressure: 150 pounds 300 pounds, can support customizationUv Nail Lamp Metal Shell

Xiamen Hongyu Intelligent Technology Co., Ltd. is one of the manufacturers specializing in the production of high-quality Uv Nail Lamp Metal Shell. You can rest assured to buy uv nail lamp metal shell from HY. We will provide you with the best after-sales service and timely delivery.

Product name: LED Nail Lamp shell

Surface treatment: sandblasting

Material: aluminum alloy

Feel: anti-fall, wear-resistant, not easy to break, smooth and textured