- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China yz250f cylinder head Manufacturers, Suppliers, Factory

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for yz250f cylinder head,yamaha r1 cylinder head,motorcycle cylinder head,harley davidson twin cam heads,sportster 1200 heads, We welcome new and aged shoppers from all walks of daily life to call us for long term business associations and mutual accomplishment!

yz250f cylinder head, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

Hot Products

Energy Vehicle Charging Gun Housing

HY is a manufacturer and supplier of Energy Vehicle Charging Gun Housing. HY precision metal stamping mold new energy vehicle charging gun stamping parts specifications: 1. The material is phosphor bronze C5191. Material thickness is 0.3mm. 2. Support surface treatment: silver plating, gold plating, nickel plating or chrome plating. 3. The seams of the stamped parts are tightly combined, without deformation, overlap, or gaps. In the drop test from a height of 2 meters in any direction, the components were not damaged.Inconel Part Oil Stamping

HY is a manufacturer and seller of custom Inconel Part Oil Stamping, Inconel part stampings are used in the petroleum industry and are very popular.hospital beds

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of medical care equipment. HY produces a wide range of products with a complete import and export qualification system. Its products are exported to Europe, the United States, the Middle East and other regions, including hospital beds, multi-functional nursing beds, electric beds, manual beds, outpatient beds, massage beds, walkers, etc. We welcome customers from all over the world to visit.

Material: medical grade stainless steel, aluminum alloy, ABS engineering plastics

Product type: hospital beds

Product use: hospital home furniture nursing beds

Product application scenarios: hospitals, nursing homes, familiesMedical Equipment Base

You can purchase Medical Equipment Base from HY with confidence, as we are a proficient producer of high-quality Medical Equipment Base. We promise to provide you with the best after-sale service and prompt delivery.

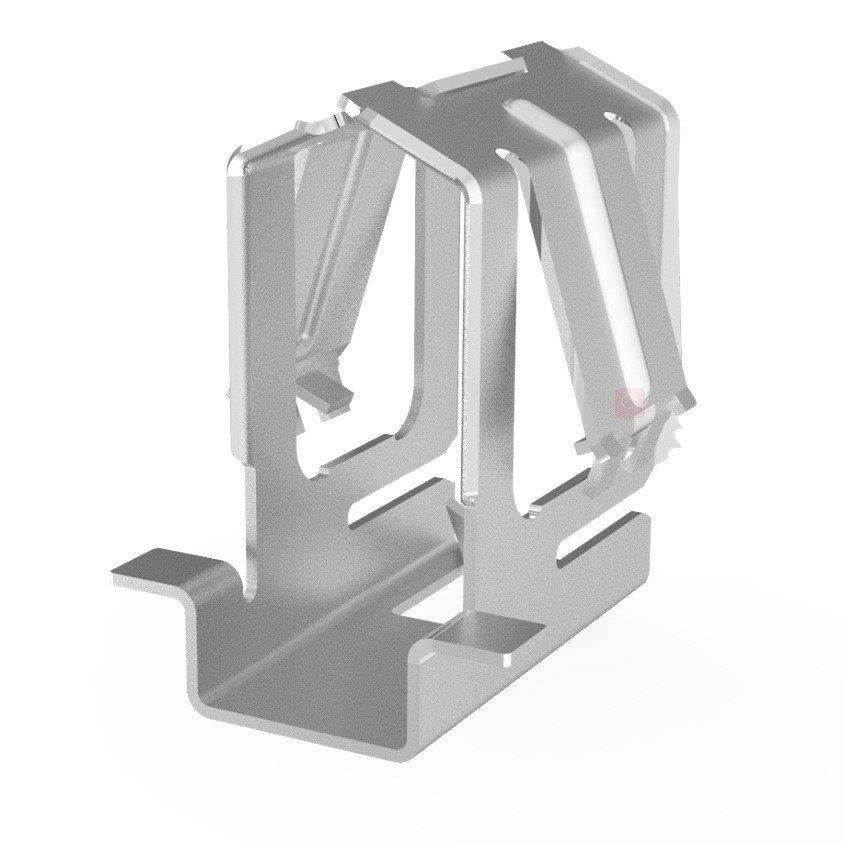

Product name: Precision sheet metal base for medical equipment

Material: Material thickness electrolytic plate

Surface treatment: electroplating anodizing

Product size: non-standard customization, customization according to drawings

Processing technology: sheet metal stamping, laser cutting, bending and riveting applications

Application areas: medical equipment automation equipmentPrecision Connector Female Terminal Copper Bar

HY is one of the Precision Connector Female Terminal Copper Bar factories in China and a supplier specializing in the production of copper terminals for connectors. Precision metal stamping connector female terminal copper bar specifications: 1. The raw material of the precision metal stamping connector female terminal copper bar is C1020, and the thickness is 10 mm. 2. After stamping, the copper bars can be nickel plated.Die Casting PWR Housing

HY as a Die Casting PWR Housing manufacturing factory. In a die-cast pressurized water reactor housing, the reactor core heats the water and maintains it under pressure to prevent it from turning into steam. This hot radioactive water flows through tubes in the steam generator.