- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

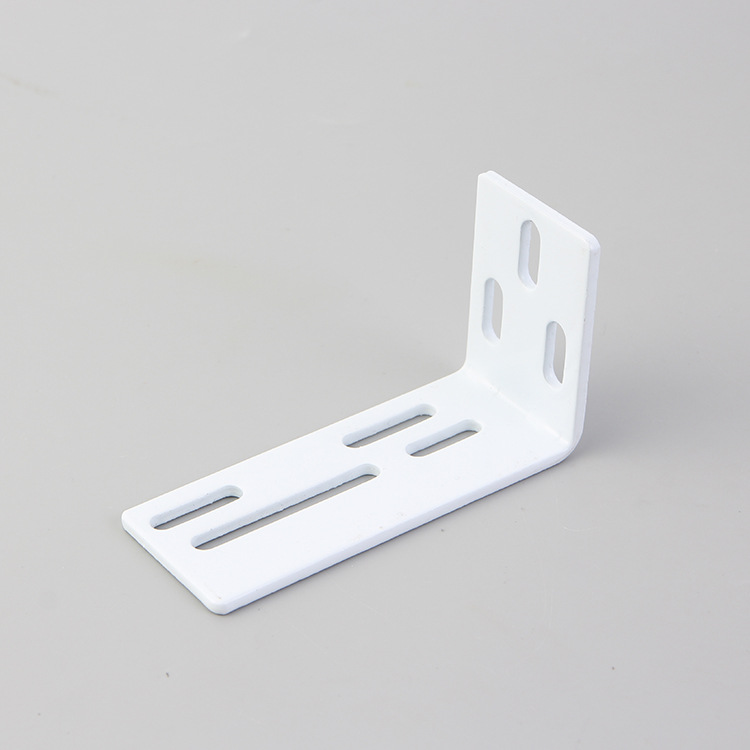

China window blind brackets Manufacturers, Suppliers, Factory

Our growth depends to the superior products ,great talents and repeatedly strengthened technology forces for window blind brackets,drapery hardware,curtain rod holders,drapery brackets,drapery hardware brackets, Our firm quickly grew in size and reputation because of its absolute dedication to superior quality manufacturing, substantial price of solutions and fantastic customer services.

window blind brackets, We believe in establishing healthy customer relationships and positive interaction for business. Close cooperation with our customers has helped us to create strong supply chains and reap benefits. Our products have gained us widespread acceptance and the satisfaction of our worldwide valued clients.

Hot Products

Casting Seeder Base-Plates

HY is a Casting Seeder Base-Plates manufacturer and seller of seeder base plates in China. High-precision castings are people’s first choice.Casting Medical Valve

HY is a medical valve factory from China. Casting Medical Valve is used to change the channel cross-sectional area and medium flow direction. It has functions such as diversion, cut-off, regulation, throttling, check, diversion or overflow pressure relief. Medical valve castings are control components in pipeline fluid delivery systems. Quality Control: 100% QC Inspection

Certification: ISO9001/CE/ROHS

Size: Support OEM/ODM customizationCasting Pulleys

HY is famous for its low price and good quality in the stamping industry. HY Casting Pulleys in almost every possible custom diameter and bore size.Bellows Expansion Joint

High quality Bellows Expansion Joint is offered by China manufacturer HY.

Product name: Corrugated expansion joint

Material: ADC12 A380

Process: die-casting + machining + surface treatment (plastic spray, silk screen)

Construction period: 45 days for mold opening + sample makingmedical tweezers

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturing company integrating production, sales and service of medical tweezers. HY is committed to strict quality control and thoughtful customer service, 24-hour engineering docking service, and is always available to discuss your requirements and ensure complete customer satisfaction. It always implements the concept of creating value for customers and tailors products for customers.

Product type: medical tweezers

Customization service: support OEM/ODM customization service

Features: corrosion-resistant, rust-proof, support high-temperature disinfection

Material: stainless steelCrimp Connectors

Xiamen Hongyu Intelligent Technology Co., Ltd. supports the customization of standard/non-standard parts of Crimp Connectors, and has more than 17 years of professional technology in hardware mold design and stamping product production. The minimum processing thickness of Crimp Connectors can reach 0.08mm, with excellent craftsmanship and no burrs.

Hongyu's advantages:

1. The selected materials far exceed the national standards

2. The service life of Stamping hardware terminals can reach more than 100,000 times

3. The durability of Crimp Connectors can reach more than 20,000 plug-in and pull-out times

4. Anti-oxidation/anti-fatigue/good rigidity/high precision