- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China drapery hardware Manufacturers, Suppliers, Factory

The buyer pleasure is our primary concentrate on. We uphold a consistent level of professionalism, excellent, credibility and service for drapery hardware,curtain rod holders,drapery brackets,drapery hardware brackets,window blind brackets, Trust us and you will gain more. Please feel free to contact us for more information, we assure you of our best attention at all times.

drapery hardware, We are proud to supply our products and solutions to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

Hot Products

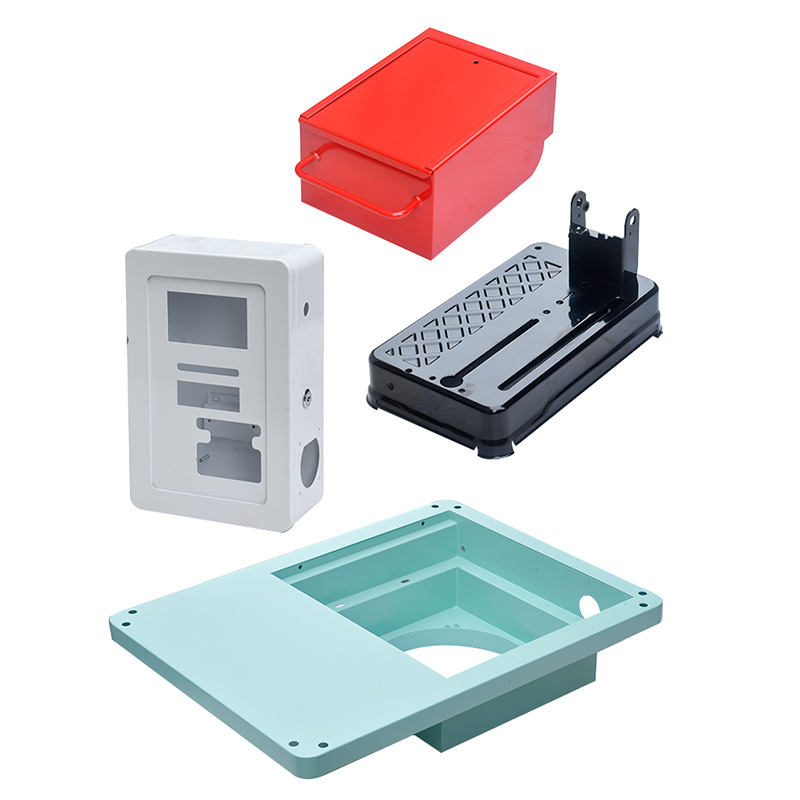

Transmission Lead-Frames

HY is a professional Transmission Lead-Frames manufacturers and suppliers in China, If you manufacture rice cookers, dryers, refrigerators, and other appliances, you rely on small components such as transmission lead frames manufactured by the best appliance stampings suppliers. This is where HY Corporation can help.Stamping Photovoltaic Junction Box

HY is a factory that specializes in customizing and Stamping Photovoltaic Junction Box.The photovoltaic junction box is an important part of the solar panel. The junction box is the housing on the module where the PV strings are electrically connected. Solar panel junction box. Most junction box manufacturers are currently located in China.Metal Stamping Industry Springs

Metal Stamping Industry Springs have been used as an important part of many areas of modern life. Industrial springs produced by HY are affordable. Therefore, designing springs with available diversity has become critical for both commercial products and industrial applications.Die Casting Main Housing

At HY, we ensure high-speed production of Die Casting Main Housing in a wide range of sizes, shapes and configurations.Hongyu is a first-class manufacturer and supplier in the Die Casting Main Housing.Gas Stove Bracket

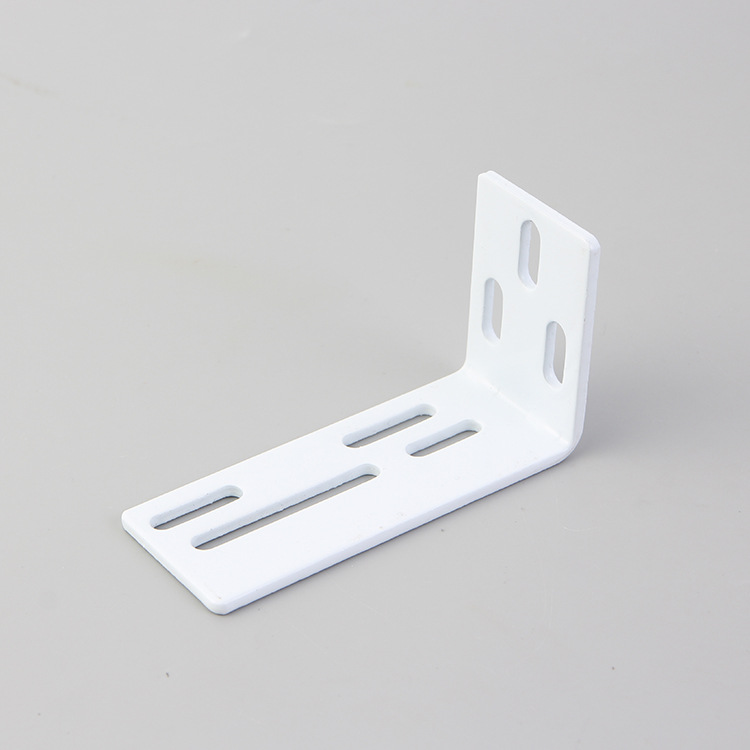

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of anti tip bracket for stove. You can order anti tip bracket for gas stove bracket from HY with confidence. We will provide you with the best after-sales service and timely delivery.

Product name: anti tip device for gas stove

Surface treatment: sandblasting anti-slip

Material: aluminum alloy, cast iron, stainless steel, customizable

Advantages: prevent high temperature oxidation and no rust, non-slip and durable, no deformation at high temperatureGaming Keyboard

HY is a manufacturer of gaming mechanical keyboards. The stamped gaming keyboard produced is a high-end product specially designed for gamers, aiming to create the most accurate, comfortable and efficient gaming experience for players. Made with high-quality materials and advanced technology, this keyboard is both durable and high-performance.