- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China stamped drive shaft Manufacturers, Suppliers, Factory

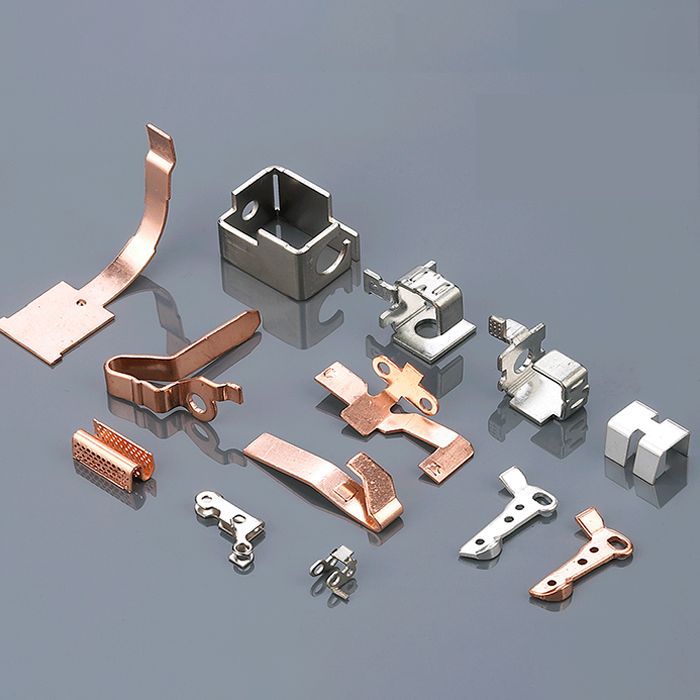

Our corporation puts emphasis about the administration, the introduction of talented staff, plus the construction of team building, attempting hard to improve the quality and liability consciousness of team members. Our organization successfully attained IS9001 Certification and European CE Certification of stamped drive shaft,universal joint drive shaft assembly,drive shaft assy,front drive shaft assembly,transmission shaft assembly, We have been sincerely wanting forward to cooperate with consumers all over the earth. We feel we can easily satisfy with you. We also warmly welcome buyers to visit our manufacturing unit and purchase our products and solutions.

stamped drive shaft, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

Hot Products

Die Cast Aluminum Light housing

As one of professional manufacturer, HY would like to provide you high quality Die Cast Aluminum Light housing. And we will offer you the best after-sale service and timely delivery.

Waterproof index: IP66 IP67

Seismic resistance index: IK08 IK09 IK10

Material: Aluminum + PC

Die-cast aluminum light housing working temperature (℃): -40-60

Certification EMC, RoHS, CE, FCC, LVD, 3G Vibration, ISO 9001, ISO 14001Meat Grinder Screw

As a leading manufacturer of meat grinder die-casting parts, HY specializes in the production of high-quality meat grinder screws. HY's screws provide precision and efficiency while ensuring perfect grinding every time. Our meat grinder screws are made of high-quality materials, making them durable and reliable even in the most demanding conditions.Die Casting Automotive Filter

Die Casting Automotive Filter,HY has extensive experience helping Chinese automakers with prototyping, designing and manufacturing aluminum and zinc alloy die castings.Casting Pulleys

HY is famous for its low price and good quality in the stamping industry. HY Casting Pulleys in almost every possible custom diameter and bore size.Engine Turbocharger

Xiamen Hongyu Intelligent Technology Co., Ltd. produces Engine Turbocharger with low price and good quality. It is a well-known domestic die-casting manufacturer. HY has a professional engineering design team and supports customized services. It can design solutions and complete the final product according to the customer's drawings or ideas.

Turbocharger molding process: high pressure casting

Surface treatment: polishing oxidation

Material: aluminum alloy

Tolerance: 0.2

Proofing cycle: 4-7 days

Processing cycle: 8-15 daysMedical Equipment Base

You can purchase Medical Equipment Base from HY with confidence, as we are a proficient producer of high-quality Medical Equipment Base. We promise to provide you with the best after-sale service and prompt delivery.

Product name: Precision sheet metal base for medical equipment

Material: Material thickness electrolytic plate

Surface treatment: electroplating anodizing

Product size: non-standard customization, customization according to drawings

Processing technology: sheet metal stamping, laser cutting, bending and riveting applications

Application areas: medical equipment automation equipment