- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China solar bracket manufacturer Manufacturers, Suppliers, Factory

We often stick to the basic principle "Quality 1st, Prestige Supreme". We are fully committed to giving our shoppers with competitively priced excellent products and solutions, prompt delivery and skilled provider for solar bracket manufacturer,solar panel brackets near me,solar panel brackets,solar panel mounting brackets,solar panel roof mounts, To significantly improve our assistance quality, our company imports a large number of international advanced devices. Welcome clients from your home and abroad to simply call and inquire!

solar bracket manufacturer, We have been introduced as a one of the growing manufacture supplier and export of our merchandise. We've got a team of dedicated trained experienced who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

Hot Products

scalpel blades

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional and reputable integrated manufacturing and trading company with many years of experience in various medical and laboratory fields. HY has established extensive and stable cooperative relations with many customers at home and abroad, with footprints in Europe, the United States, the Middle East and Russia, and can provide you with one-stop medical and laboratory product services.

Type: scalpel blades

Features: removable and replaceable, complete specifications

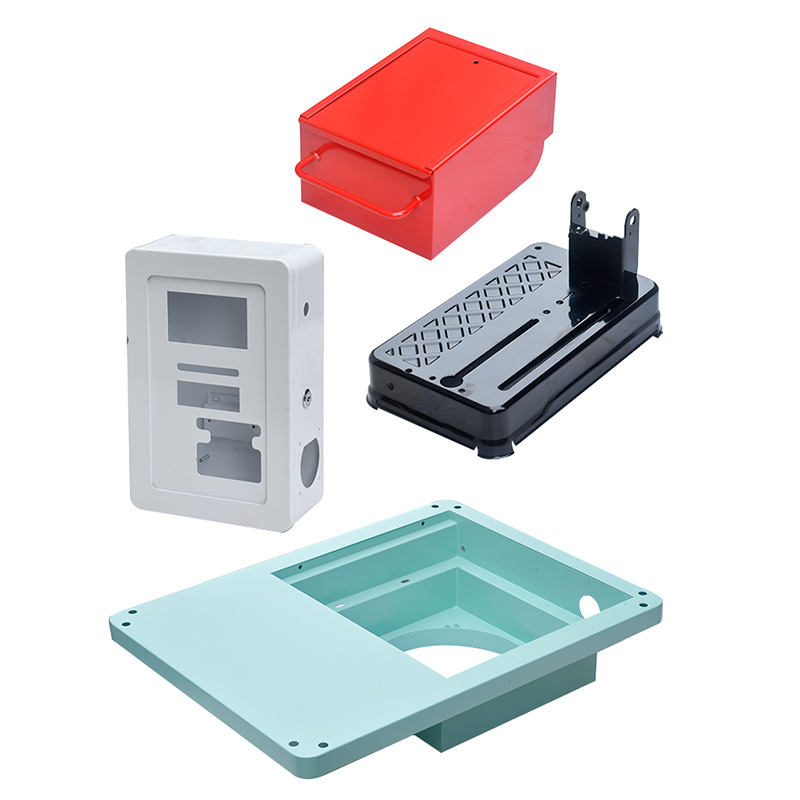

Material: carbon steel, stainless steelauto battery tray

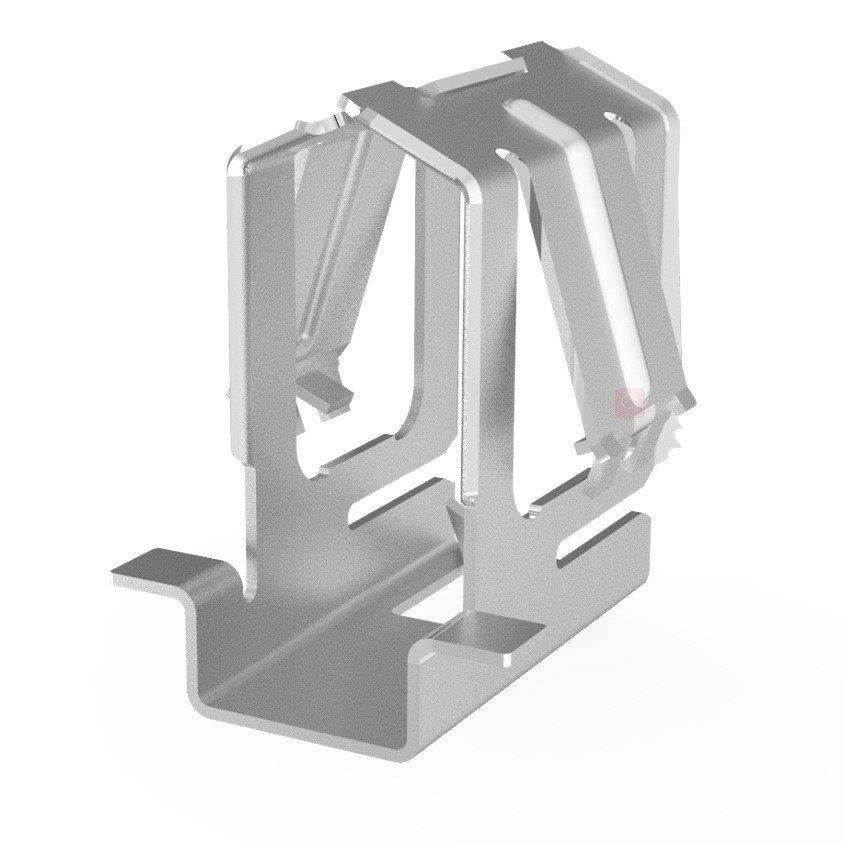

Xiamen Hongyu Intelligent Technology Co., Ltd. has been committed to the development of low-voltage components, lighting components, automation components, medical equipment components, communication components and precision equipment components. We have been committed to stamping and assembly production for many years. We have accumulated rich experience in the field of auto battery tray. Our products are widely used in various high-power battery packs, electric vehicle battery packs, solar street lights, military battery packs, etc., which can meet the needs of most customers. The battery trays produced by HY have different shapes and standards. We can provide customized technical services for various application scenarios according to customer needs.

Process: aluminum stamping, aluminum extrusion, precision machining, welding assembly

Surface treatment: spraying, black, galvanizing

Application scenarios: automobiles, electric vehicles, ships, etc.Transmission Lead-Frames

HY is a professional Transmission Lead-Frames manufacturers and suppliers in China, If you manufacture rice cookers, dryers, refrigerators, and other appliances, you rely on small components such as transmission lead frames manufactured by the best appliance stampings suppliers. This is where HY Corporation can help.Hair Dryer Filter

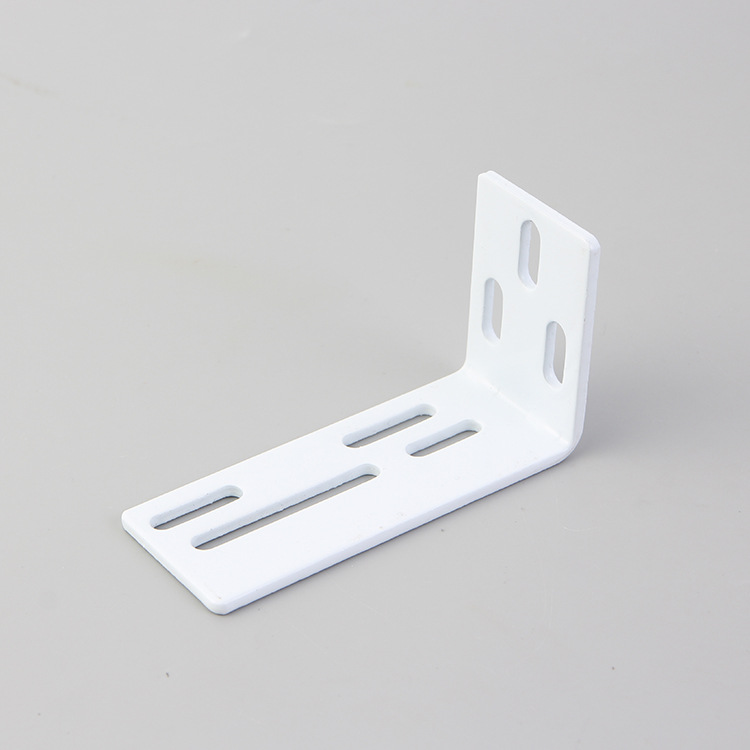

Xiamen Hongyu Intelligent Technology Co., Ltd. has 17 years of processing and manufacturing experience and has been providing high-quality Hair Dryer Filter to customers at home and abroad. The filter hair dryer we produce is light in weight, has good stability, and has good anti-oxidation filtration. It can effectively use manufacturing processes such as stamping and etching to save materials and reduce production costs. Material: 304 stainless steel, aluminum alloy, titanium, nickel-based alloy, etc. Specifications: Customizable Use scenarios: home, hotel, barber shop, etc.Curtain Bracket

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional Stamping Curtain Bracket Supplier, using precision metal stamping technology, good quality and low price.

Product name: curtain bracket

Material: stainless steel

Process: Progressive stamping die

Type: Hardware metal stamping

Industry: hangers, brackets, curtainsknee crutch

Xiamen Hongyu Intelligent Technology Co., Ltd. is one of the leading medical device manufacturers and exporters in China, specializing in the research and development and sales of medical devices. It has provided various medical equipment and rehabilitation equipment to mainland China for many years. HY produces various types of assistive devices, including walkers, crutches, forearm crutches, underarm crutches, hands-free crutches, knee crutch, wheelchairs, nursing beds, commode chairs, etc.

Product: Hands-Free Single Crutch

Material: Aluminum Alloy

Features: Assisted walking