- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Sensor Components For Iot Devices Manufacturers, Suppliers, Factory

With this motto in mind, we now have turn out to be amongst quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for Sensor Components For Iot Devices,Sensor Components Online,Linear Potentiometer Sensor,Top Sensor Component,Affordable Sensor Components, We have been keeping chasing WIN-WIN problem with our purchasers. We warmly welcome consumers from everywhere in the planet coming in excess of for a visit and establishing long-term connection.

Sensor Components For Iot Devices, Now we have constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and professional after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Hot Products

lunch box

Xiamen Hongyu Intelligent Technology Co., Ltd. has been committed to the development and production of stamping and die-casting products for many years, such as kitchen household products, stainless steel lunch box forks and spoons, lunch boxes, water cups, baby products and many other series. A company specializing in the production and processing of quality management system, honest management, quality assurance, self-production and self-sales, reasonable prices, HY has been widely praised in the European, American and Middle Eastern markets and won the trust of consumers, and has been recognized by the industry with its integrity, strength and product quality. Friends from all walks of life are welcome to visit, guide and negotiate business.

Type: lunch box, kids lunch box, stainless steel lunch box

Material: 304/316 food grade stainless steel

Customization: support OEM/ODM customizationCustom Metal Stamping Dies

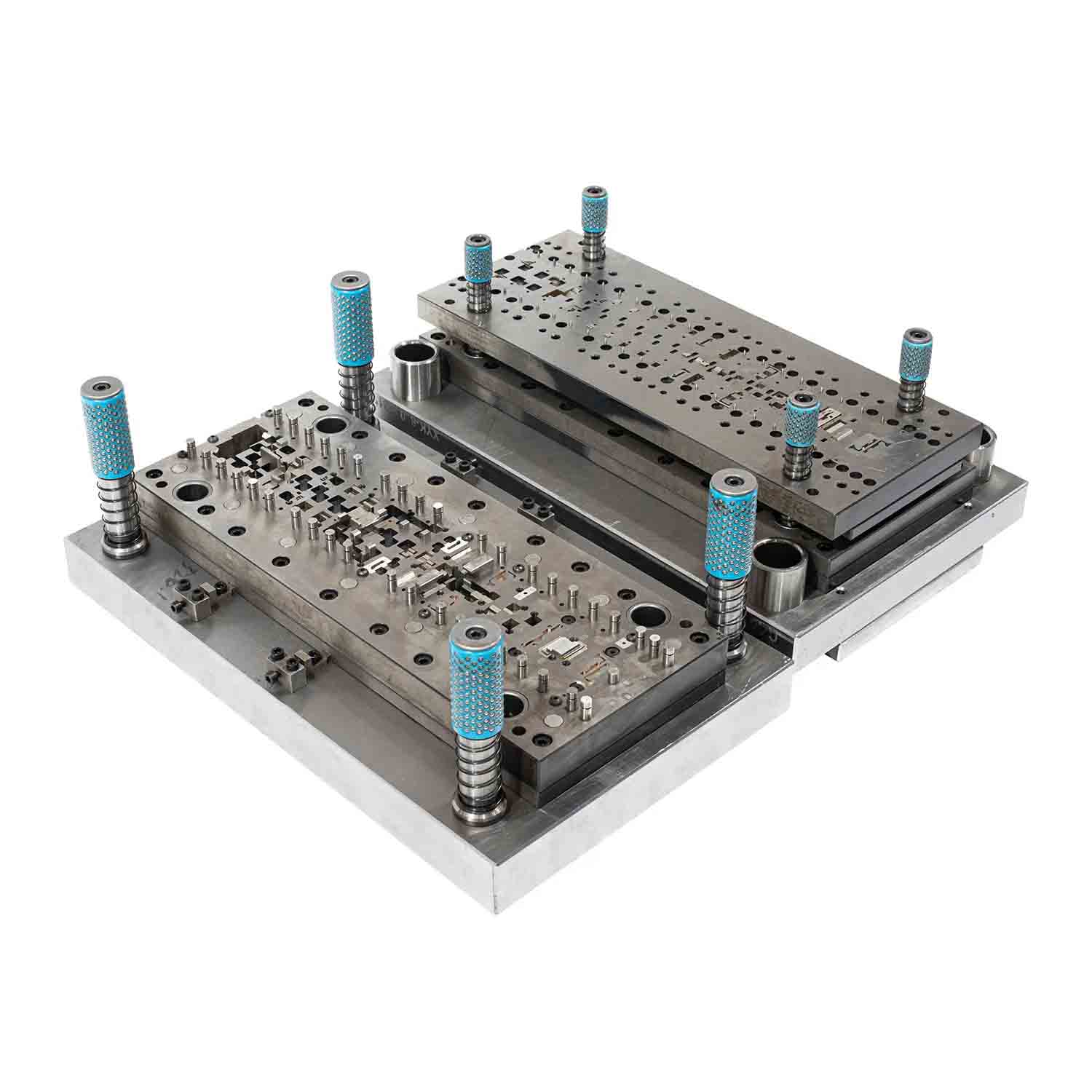

Xiamen Hongyu Intelligent Technology Co., Ltd.'s Custom Metal Stamping Dies are widely used in the automotive, medical and aerospace industries, focusing on precision tools for producing high-quality metal parts. Custom Metal Stamping Dies are usually made of high-strength materials such as steel or carbide, and HY can customize the design according to the specific needs of each customer.

Surface treatment: nickel plating, tin plating, zinc plating, chrome plating, heat treatment, electroplating, etc.

Design file format: dwg, dxf, step, x_t, top, igs

Mold life: Under normal use, the life of the mold can reach at least 300,000 cycles.Casting Seeder Base-Plates

HY is a Casting Seeder Base-Plates manufacturer and seller of seeder base plates in China. High-precision castings are people’s first choice.crutch

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturing factory that produces various wheelchairs, commode chairs, shower chairs, crutch, walkers and other medical rehabilitation products. With more than 17 years of processing and manufacturing experience, our factory has passed IS013485 and IS09001 quality management, and the products have passed CE certification.

Product type: crutch

Use: medical rehabilitation supplies

Color: matte, metallic, silvershutters

Xiamen Hongyu Intelligent Technology Co., Ltd. is a dynamic modern enterprise with more than 10 years of experience in manufacturing aluminum windows and doors and metal shutters. HY's products are available in a variety of colors and sizes, and our product range can be customized according to the customer's plans and requirements. If you are buying shutters for the first time, we will provide professional advice on the selection of profiles. Different regions have different climatic characteristics, so different profiles should be treated differently to meet their diversity, which is related to the durability of doors and windows and each function of absorbing and saving energy.

Types: metal shutters, aluminum window shutters, steel shutters

Customization service: support OEM/ODM customization

Application scenarios: home, hotel, B&B, factory, ventilationMetal Stamping Industry Springs

Metal Stamping Industry Springs have been used as an important part of many areas of modern life. Industrial springs produced by HY are affordable. Therefore, designing springs with available diversity has become critical for both commercial products and industrial applications.