- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China holset turbo Manufacturers, Suppliers, Factory

HY is a professional holset turbo manufacturers and suppliers in China. Welcome to our factory to buy holset turbo. Our high quality products is not only made in China and we have quotation.

Hot Products

Gas Stove Bracket

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of anti tip bracket for stove. You can order anti tip bracket for gas stove from HY with confidence. We will provide you with the best after-sales service and timely delivery.

Product name: anti tip device for gas stove

Surface treatment: sandblasting anti-slip

Material: aluminum alloy, cast iron, stainless steel, customizable

Advantages: prevent high temperature oxidation and no rust, non-slip and durable, no deformation at high temperatureEngine Turbocharger

Xiamen Hongyu Intelligent Technology Co., Ltd. produces Engine Turbocharger with low price and good quality. It is a well-known domestic die-casting manufacturer. HY has a professional engineering design team and supports customized services. It can design solutions and complete the final product according to the customer's drawings or ideas.

Turbocharger molding process: high pressure casting

Surface treatment: polishing oxidation

Material: aluminum alloy

Tolerance: 0.2

Proofing cycle: 4-7 days

Processing cycle: 8-15 daysDie Casting Main Housing

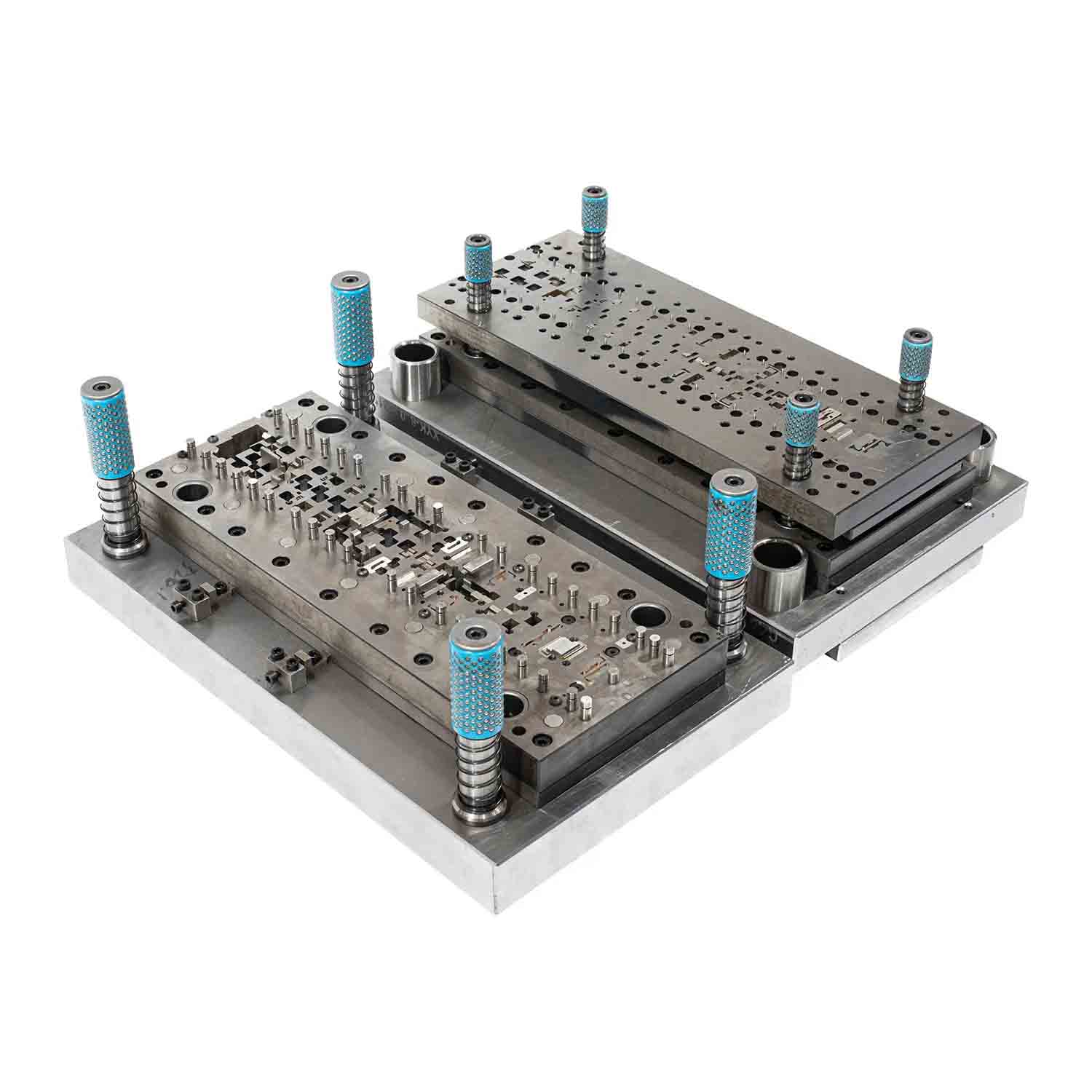

At HY, we ensure high-speed production of Die Casting Main Housing in a wide range of sizes, shapes and configurations.Hongyu is a first-class manufacturer and supplier in the Die Casting Main Housing.Custom Metal Stamping Dies

HY Custom Metal Stamping Dies are used in the automotive, medical and aerospace industries, focusing on precision tools that produce high-quality metal parts. Metal stamping dies are usually made of steel or carbide, a strong and durable material, and HY can custom design them to meet each customer's specific needs.Precision Hardware Stamped Aluminum Plate

HY Precision Hardware Stamped Aluminum Plate specifications: 1. The HY precision metal stamped aluminum disc is made of aluminum with a thickness of 0.4mm. 2. This product is used in climate conditioners. 3. The product has high sealing performance and stability.Die Casting Automotive Filter

Die Casting Automotive Filter,HY has extensive experience helping Chinese automakers with prototyping, designing and manufacturing aluminum and zinc alloy die castings.