- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China hellcat differential Manufacturers, Suppliers, Factory

That has a positive and progressive attitude to customer's fascination, our enterprise constantly improves our merchandise high quality to meet the demands of customers and further focuses on safety, reliability, environmental requirements, and innovation of hellcat differential,bmw differential,350z differential,chevy differential,bmw rear differential, Through our hard work, we have always been on the forefront of clean technology product innovation. We are a green partner you can rely on. Contact us today for more information!

hellcat differential, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

Hot Products

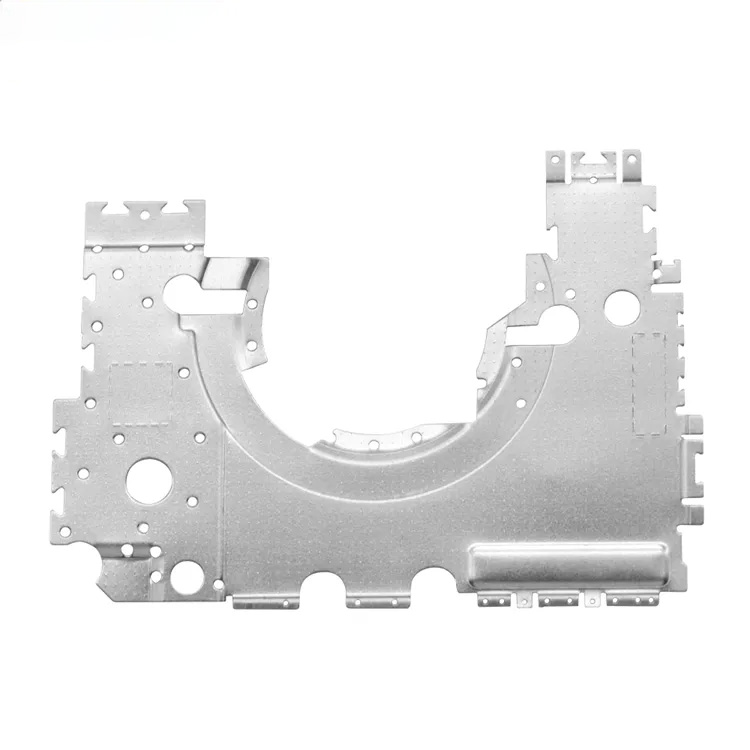

Mobile Phone Stainless Steel Stamping Parts

HY sixteen years of industry experience Material: SUS301 Mobile Phone Stainless Steel Stamping Parts specifications: customized according to customer requirements Material characteristics: complies with ROHS, SGS testing Qualification certification: ISO9001 & IATF16949Stamping Photovoltaic Junction Box

HY is a factory that specializes in customizing and Stamping Photovoltaic Junction Box.The photovoltaic junction box is an important part of the solar panel. The junction box is the housing on the module where the PV strings are electrically connected. Solar panel junction box. Most junction box manufacturers are currently located in China.Die Casting Mechanical And Electrical Shroud Fan

HY Zinc alloy Die Casting Mechanical And Electrical Shroud Fan factory. Part material: Zamak 2/3/5/7 Industry: Home appliance industry, electromechanical industry Number of chambers: 1*1, 1*2Casting Medical Gas Outlet

HY is a factory qualified for the production of medical gas outlet for export.Casting medical gas outlet should be gas-specific with a gas-specific indexing pin arrangement to connect the lock valve assembly only to the specifically matched gas back body, preventing interchangeability of gas services.Casting Gearbox Components

Hongyu Intelligent specializes in die-casting many important transmission components for the automotive and heavy-duty Casting Gearbox Components Manufacturing stamping industry.stroller frame for car seat

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company that designs, develops, produces, sells and provides after-sales services. As an exporter of Chinese baby-related industries, it has exported stroller frames for car seats to more than 20 countries around the world. HY has always taken design, research and development and strong after-sales services as the core of our strategy, strictly controlling each product to ensure the customer's after-sales experience. HY welcomes global customers to discuss cooperation.

Type: Stroller frame for car seat

Fabric: Oxford cloth, high-grade leather, etc.

Material: Aluminum alloy, high carbon steel, special alloys support customization

Application scenarios: outdoor/home/camping/multi-purpose passenger cars/RVs/family cars, etc.

Processing technology: metal die-casting