- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Die-cast meat grinder screw Manufacturers, Suppliers, Factory

Adhering towards the theory of "quality, support, efficiency and growth", we've attained trusts and praises from domestic and international client for Die-cast meat grinder screw,meat grinder screw,High-Quality Screw for Meat Grinder,Die cast meat grinder accessories,Hot Chamber Die Casting, We are expecting to cooperate with you on the basis of mutual benefits and common development. We will never disappoint you.

Die-cast meat grinder screw, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we now have a pleasant and long terms business together!!!

Hot Products

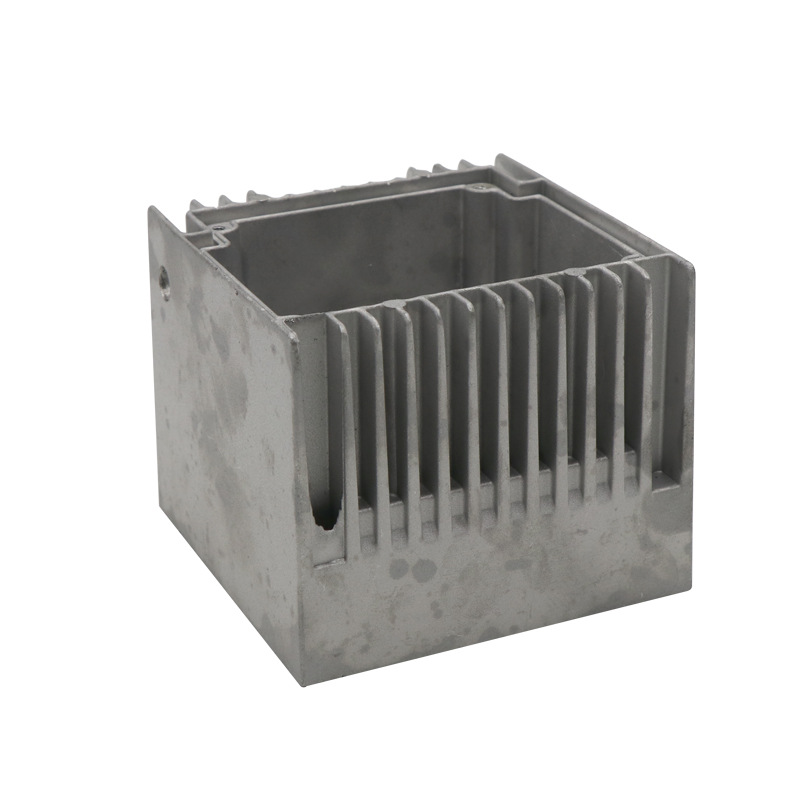

Heat Sink

The Heat Sink produced by Xiamen Hongyu Intelligent Technology Co., Ltd. is mainly made of aluminum die casting. HY, as an Aluminum die casting heat sink factory, has 17 years of manufacturing experience in this industry. A heat sink is a heat exchanger that transfers heat from a heating device or heat source to the surrounding fluid, usually made of copper or aluminum. Material: 6000 series, such as alloy 6063/6061/6005, etc. Shape: square, round, support customization Color: silver, black, gold, champagne, support customization Application scenarios: IC circuit boards, motherboards, transistors, etc.Metal Brand Seal

Customized Metal Brand Seal, mirror polished, solid brass HY designs a unique seal taste for you. The iconic "shiny" head is machined from a solid brass blank and coated with an ultra-fine ceramic layer.Gas Stove Bracket

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of anti tip bracket for stove. You can order anti tip bracket for gas stove bracket from HY with confidence. We will provide you with the best after-sales service and timely delivery.

Product name: anti tip device for gas stove

Surface treatment: sandblasting anti-slip

Material: aluminum alloy, cast iron, stainless steel, customizable

Advantages: prevent high temperature oxidation and no rust, non-slip and durable, no deformation at high temperatureStainless steel flat washer

HY developed metal stamped stainless steel flat washers for customers in the medical industry. Made from 17-7 PH stainless steel, this stainless steel gasket has strong corrosion resistance and is not prone to rust, making it ideal for medical use.Motor Cooling Fan Blade

Motor cooling fan blade material: aluminum, Manufacturing process: die casting, Surface treatment: anodizing, powder coating, Application industry: industrial machinery, Die casting time: 100 pieces/hour,stainless steel screws

Xiamen Hongyu Intelligent Technology Co., Ltd. specializes in the production of hardware accessories. It is a high-quality enterprise with "professionalism, innovation and service" as its core, and has therefore won the recognition and trust of customers. HY is committed to the research and development, production and sales of stainless steel screws fasteners, including 13 invention patents, 15 utility model patents and 1 design patent, demonstrating our technical expertise and innovation capabilities.

Hardware accessories: screw

Material: stainless steel, steel, brass, titanium, carbon steel, nickel, alloy

Surface treatment: black, galvanized

Quality: 100% full inspection, test and certification can be carried out according to customer special requirements