- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

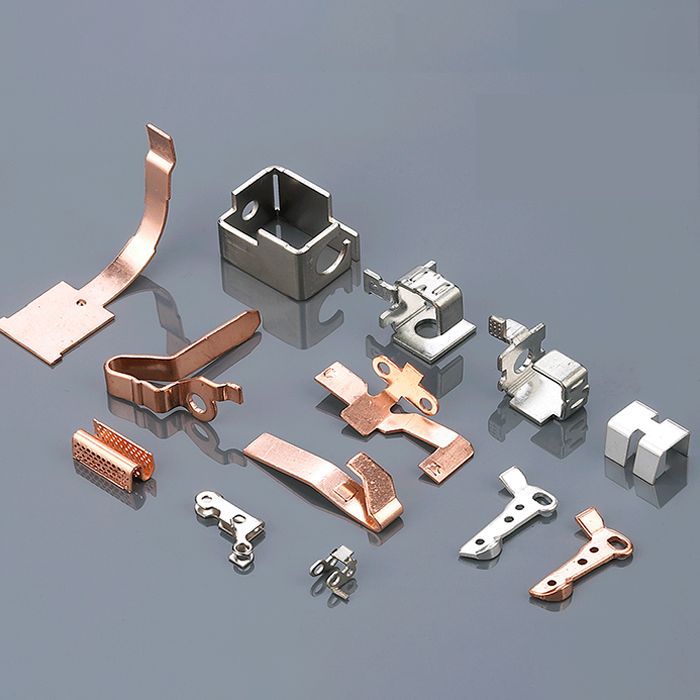

China Custom metal stamp Stainless steel flat washer Manufacturers, Suppliers, Factory

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We are able to assure you product or service quality and aggressive cost for Custom metal stamp Stainless steel flat washer,Metal stamping Stainless steel flat washer,stamping Stainless steel flat washer, We adhere towards the tenet of "Services of Standardization, to fulfill Customers' Demands".

Custom metal stamp Stainless steel flat washer, We believe with our consistently excellent service you can get the best performance and cost least goods from us for a long term . We commit to provide better services and create more value to all our customers. Hope we can create a better future together.

Hot Products

lunch box

Xiamen Hongyu Intelligent Technology Co., Ltd. has been committed to the development and production of stamping and die-casting products for many years, such as kitchen household products, stainless steel lunch box forks and spoons, lunch boxes, water cups, baby products and many other series. A company specializing in the production and processing of quality management system, honest management, quality assurance, self-production and self-sales, reasonable prices, HY has been widely praised in the European, American and Middle Eastern markets and won the trust of consumers, and has been recognized by the industry with its integrity, strength and product quality. Friends from all walks of life are welcome to visit, guide and negotiate business.

Type: lunch box, kids lunch box, stainless steel lunch box

Material: 304/316 food grade stainless steel

Customization: support OEM/ODM customizationMetal Stamping Fuse Boxes

HY is a manufacturer and trader of Metal Stamping Fuse Boxes. HY metal stamped fuse box is made of stainless steel, which is rust-proof, anti-fouling, has higher strength, hardness and ductility. Precision metal stamping is used in many industries.Die Casting Windshield Wiper

HY is a Die Casting Windshield Wiper factory that provides aluminum die-cast windshield wipers. Commonly used materials for die-cast wiper rods: a380, adc12, alsi9cu3, zl104; surface smoothness of rough parts: ra1.6~ra3.2;Die Casting Mechanical And Electrical Shroud Fan

HY Zinc alloy Die Casting Mechanical And Electrical Shroud Fan factory. Part material: Zamak 2/3/5/7 Industry: Home appliance industry, electromechanical industry Number of chambers: 1*1, 1*2Pc Fan Bracket

Xiamen Hongyu Intelligent Technology Co., Ltd. is an ISO enterprise specializing in the manufacture of hardware accessories. It has more than 17 years of processing experience. Including pc fan bracket, sheet metal CNC processing, shell, bracket, chassis design, and the production and manufacturing of internal functional parts of products. High quality, on-time delivery, professional design, and one-stop service are the reasons for our long-term cooperation with well-known customers such as HAN's LASER, Formlabs, Samurai, Baxter, VELKASE, etc. As long as you give us the function, performance, and even creativity of the product, we can turn the product from creativity into reality. Welcome to consult immediately.

Item: computer case fan bracket

Certificate: ISO9001:2008

Customization: Support customized OEM serviceSelective Plated Terminals

HY is a factory that Selective Plated Terminals progressive high-speed stamping dies.OEM metal progressive high speed stamping die for selective plated terminals part/press machine/electrical jack metal part/electrical appliance metal hook buckle。