- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China automobile laptop desk Manufacturers, Suppliers, Factory

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for automobile laptop desk,car folding table,steering wheel desk,table for car seat,automobile computer desk, We have been prepared to offer you the top suggestions on the designs of one's orders in a professional way if you need. During the meantime, we retain on developing new technologies and building new designs so as for making you ahead within the line of this business.

automobile laptop desk, Many products fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't have to waste time shopping around.

Hot Products

Casting Gearbox Components

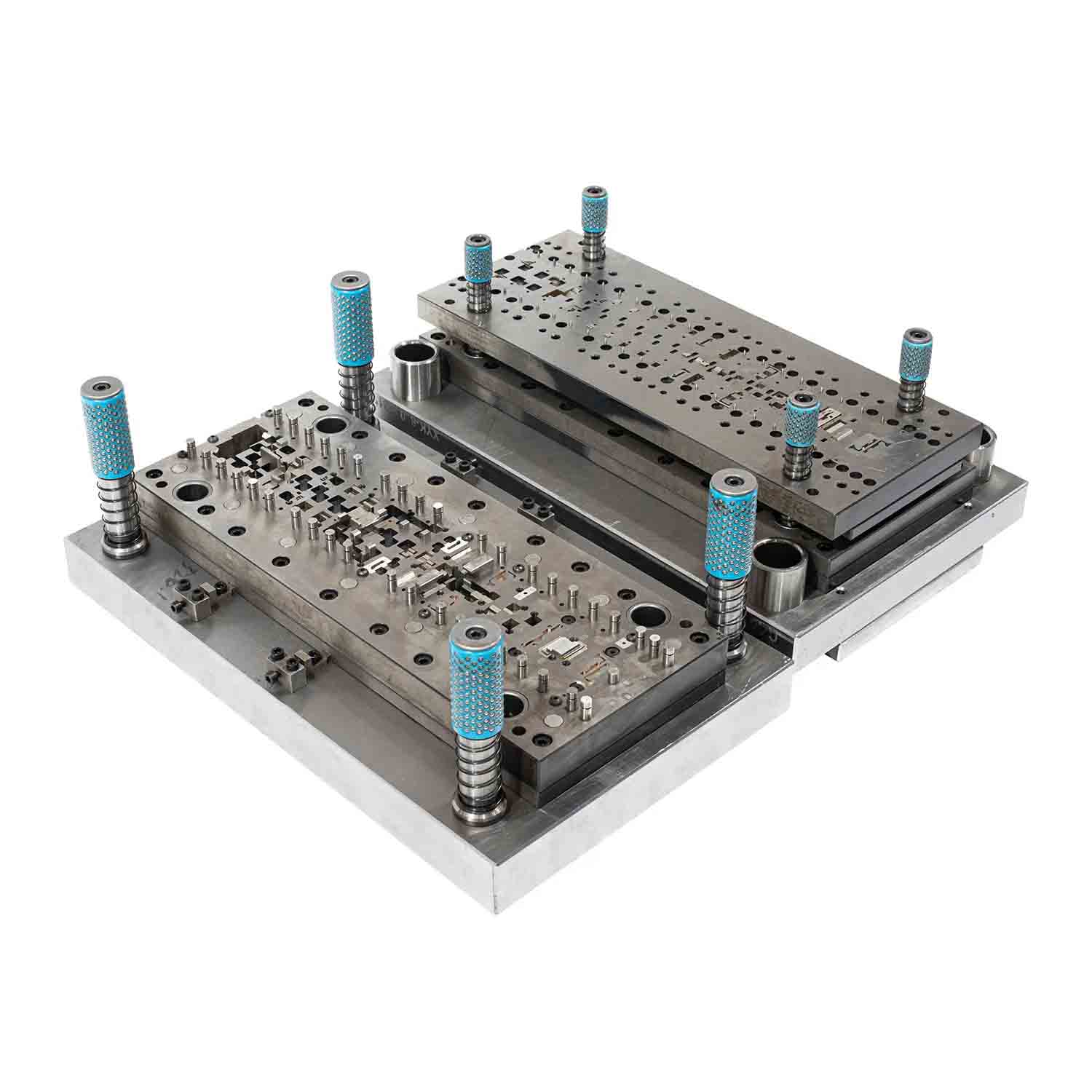

Hongyu Intelligent specializes in die-casting many important transmission components for the automotive and heavy-duty Casting Gearbox Components Manufacturing stamping industry.Aluminum Flange

Xiamen Hongyu Intelligent Technology Co., Ltd. specializes in providing a series of products such as aluminum flanges, elbows, and pipe fittings. We will use different materials for processing according to the customer's usage scenarios and needs, such as stainless steel, carbon steel, alloy steel, etc. The products are widely used in petroleum, chemical, machinery, electricity, metallurgy, etc. The company's products support material, specification model, non-standard drawings, and customized packaging.

Processing technology: forging and casting

Keywords: ductwork flange

Application: pipeline connection

Flange type: slip-on welding flangeAluminum Die Casting Flashlight Lighting

HY is a factory that Aluminum Die Casting Flashlight Lighting high-precision stamping and die-casting.Die casting has proven to be an effective method of producing different parts using different materials: copper, zinc and aluminum alloys. Aluminum die casting various properties make it a good metal for die casting.electric hospital bed

Xiamen Hongyu Intelligent Technology Co., Ltd. is a comprehensive medical care enterprise covering R&D, production, sales and after-sales service. It combines processing technology with national environmental certification materials and has a series of product production lines covering intermediate care beds, operating beds, electric hospital beds, etc. HY is committed to promoting medical care into an era of intelligent innovation, giving patients and medical staff more health and humanistic care.

Material: medical grade stainless steel, aluminum alloy, ABS engineering plastics

Product type: electric hospital bed

Product use: hospital home furniture nursing bed

Product application scenario: hospital, nursing homeDie Casting Windshield Wiper

HY is a Die Casting Windshield Wiper factory that provides aluminum die-cast windshield wipers. Commonly used materials for die-cast wiper rods: a380, adc12, alsi9cu3, zl104; surface smoothness of rough parts: ra1.6~ra3.2;Spark Plug

Xiamen Hongyu Intelligent Technology Co., Ltd. is a leading and well-known manufacturer of high-end automotive engine spark plugs. Its electrodes are made of high-quality metal iridium and platinum, suitable for various cars, such as CORROLA, RAV4, CAMRY, TOYOTA VOIS, ALPHA car engines. Our spark plugs are made of high-quality raw materials and have excellent engine performance.

Main products: double iridium, double platinum, iridium platinum, single iridium, single platinum, nickel, CNG, LPG special vehicle high-end spark plugs

Electrode material: iridium

OEM customization: support