- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China aluminum alloy die casting Manufacturers, Suppliers, Factory

Our growth depends within the innovative equipment, fantastic talents and repeatedly strengthened technology forces for aluminum alloy die casting,aluminum casting alloys,die cast metal,aluminium die casting process,aluminum die casting manufacturer, Our experienced specialized workforce will probably be wholeheartedly at your provider. We sincerely welcome you to check out our web-site and organization and mail us your inquiry.

aluminum alloy die casting, With more and more Chinese solutions around the world, our international business is developing rapidly and economic indicators big increase year by year. We've enough confidence to provide you both better items and service, because we have been more and more powerful, professional and experience in domestic and international.

Hot Products

stainless steel rivets

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of all kinds of stainless steel rivets, blind rivets, rivet nuts, pressure rivets, national standard fasteners, non-standard fasteners, and riveting tools. The company has a complete set of advanced production equipment and automatic lathes, and adopts international advanced standards for production. "Zero defects, create brands" is HY's purpose. We hope to establish a good cooperative relationship with domestic and foreign customers on the basis of equality, mutual benefit and common development.

Surface treatment: natural, black, galvanized, other

Material: stainless steel, aluminum, brass, special alloy

Processing technology: stampingDie Casting Automotive Filter

Die Casting Automotive Filter,HY has extensive experience helping Chinese automakers with prototyping, designing and manufacturing aluminum and zinc alloy die castings.Engine Turbocharger

Xiamen Hongyu Intelligent Technology Co., Ltd. produces Engine Turbocharger with low price and good quality. It is a well-known domestic die-casting manufacturer. HY has a professional engineering design team and supports customized services. It can design solutions and complete the final product according to the customer's drawings or ideas.

Turbocharger molding process: high pressure casting

Surface treatment: polishing oxidation

Material: aluminum alloy

Tolerance: 0.2

Proofing cycle: 4-7 days

Processing cycle: 8-15 daysCasting Medical Valve

HY is a medical valve factory from China. Casting Medical Valve is used to change the channel cross-sectional area and medium flow direction. It has functions such as diversion, cut-off, regulation, throttling, check, diversion or overflow pressure relief. Medical valve castings are control components in pipeline fluid delivery systems. Quality Control: 100% QC Inspection

Certification: ISO9001/CE/ROHS

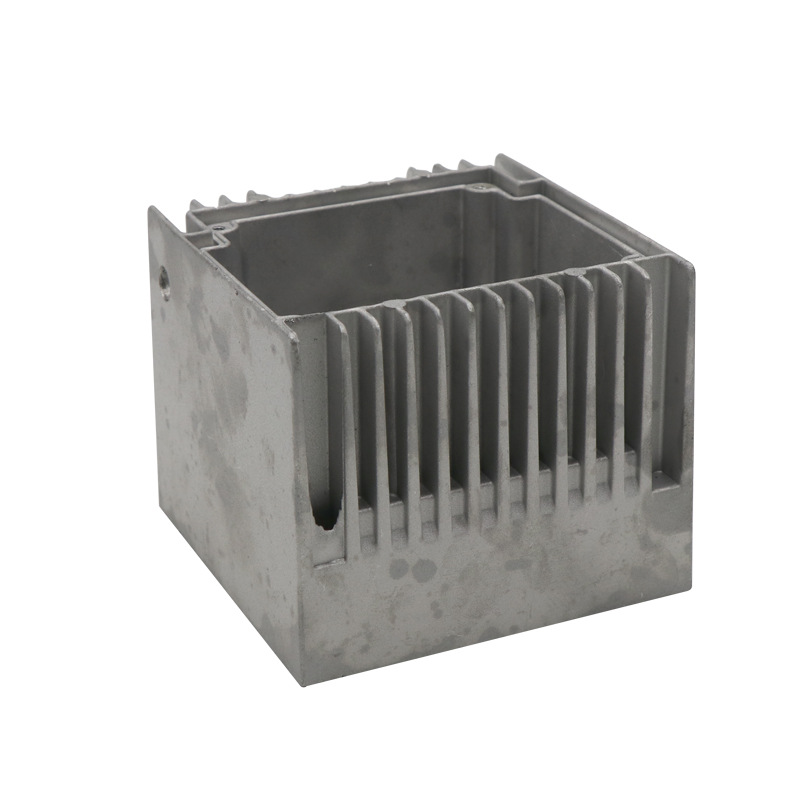

Size: Support OEM/ODM customizationHeat Sink

The Heat Sink produced by Xiamen Hongyu Intelligent Technology Co., Ltd. is mainly made of aluminum die casting. HY, as an Aluminum die casting heat sink factory, has 17 years of manufacturing experience in this industry. A heat sink is a heat exchanger that transfers heat from a heating device or heat source to the surrounding fluid, usually made of copper or aluminum. Material: 6000 series, such as alloy 6063/6061/6005, etc. Shape: square, round, support customization Color: silver, black, gold, champagne, support customization Application scenarios: IC circuit boards, motherboards, transistors, etc.Curtain Bracket

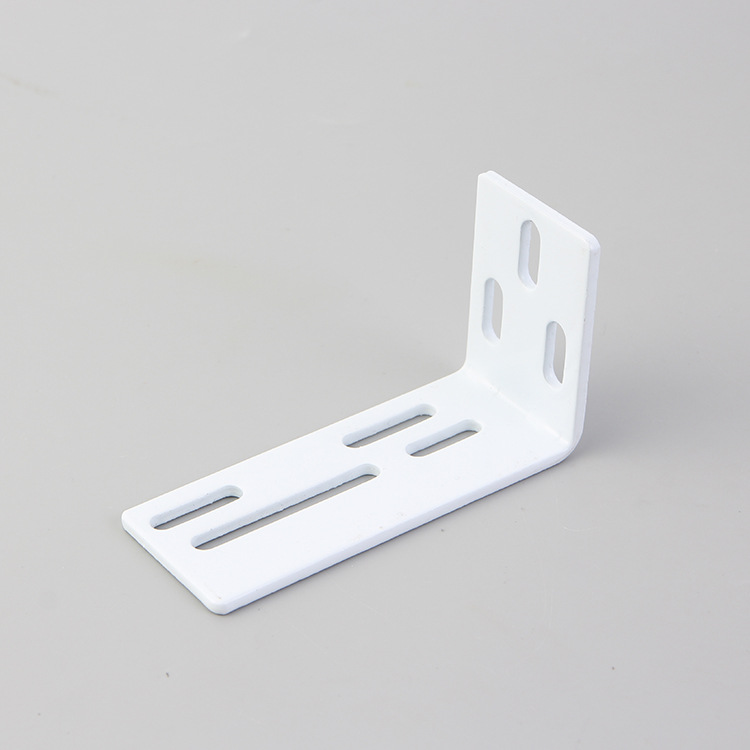

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional Stamping Curtain Bracket Supplier, using precision metal stamping technology, good quality and low price.

Product name: curtain bracket

Material: stainless steel

Process: Progressive stamping die

Type: Hardware metal stamping

Industry: hangers, brackets, curtains