- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China stainless steel check valve flanged Manufacturers, Suppliers, Factory

Excellent comes 1st; service is foremost; small business is cooperation" is our organization philosophy which is regularly observed and pursued by our company for stainless steel check valve flanged,flange check valve,3 flanged check valve,back flow valve,non return valve, We price your inquiry, For more facts, please get in touch with us, we will reply you ASAP!

stainless steel check valve flanged, Our next goal is to exceed the expectations of every client by offering outstanding customer service, increased flexibility and greater value. All in all, without our customers we do not exist; without happy and fully satisfied customers, we fail. We have been looking for the wholesale, Drop ship. Please contact us if you are interesting our items. Hope to do business with you all. High quality and fast shipment!

Hot Products

Metal Stamping Fasteners

HY improve and design industrial fasteners by Metal Stamping Fasteners, providing lower-cost precision metal stamping parts, and more efficient alternative solutions. Metal stampings are commonly used in nearly every industry, including electrical, automotive, appliances, and construction.Engine Turbocharger

Xiamen Hongyu Intelligent Technology Co., Ltd. produces Engine Turbocharger with low price and good quality. It is a well-known domestic die-casting manufacturer. HY has a professional engineering design team and supports customized services. It can design solutions and complete the final product according to the customer's drawings or ideas.

Turbocharger molding process: high pressure casting

Surface treatment: polishing oxidation

Material: aluminum alloy

Tolerance: 0.2

Proofing cycle: 4-7 days

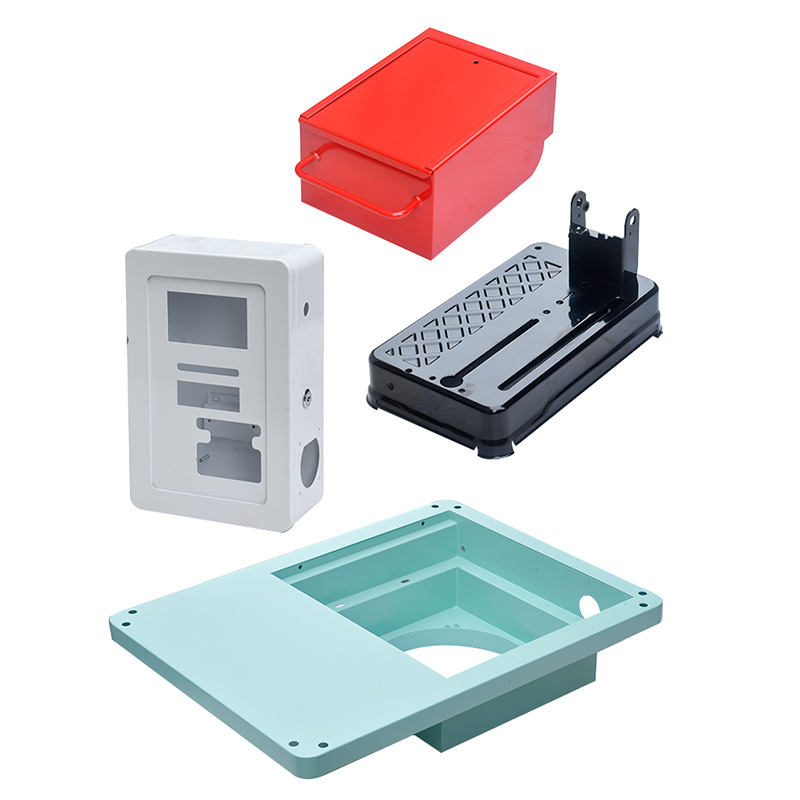

Processing cycle: 8-15 daysDie Casting Chassis

HY is committed to producing Die Casting Chassis to provide optimal strength and is a manufacturer and trader of stamping and die-cast products. enhance the power of the frame. The materials used are carefully and rigorously selected to extend the service life.Metal Stamping Fuse Clips

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company specializing in the production of Metal Stamping Fuse Clips. The function of Metal Stamping Fuse Clips is to connect the circuit and the fuse. It is part of the protection circuit and can facilitate the installation and removal of the fuse. HY specializes in the production of various types of metal stamping parts and sheet metal processing parts, and has been committed to the research and development and improvement of related technologies. For the stamping business, we have strong mold, design and production capacity, can design and manufacture new molds, respond to changes very quickly, and provide solutions for various difficult metal stamping parts.

Product Type: Metal Stamping Fuse Clips, Brass Fuse Clips, Pcb Mount Fuse Clips

Surface treatment: anodizing, polishing, electroplating, PVD coating, galvanizing

Drawing format: CAD, 3D (stp, igs, dfx). PDF

Tolerance: +-0.01-0.05 mm can be more precise, according to your requirementsTransmission Lead-Frames

HY is a professional Transmission Lead-Frames manufacturers and suppliers in China, If you manufacture rice cookers, dryers, refrigerators, and other appliances, you rely on small components such as transmission lead frames manufactured by the best appliance stampings suppliers. This is where HY Corporation can help.solar mounting system

Xiamen Hongyu Intelligent Technology Co., Ltd. is a high-tech enterprise specializing in the research and development, production, sales and service of solar photovoltaic support systems in the new energy industry. These products have been sold to more than 100 countries and regions including the United States, the European Union, Australia, the Middle East, South Africa, Japan and Southeast Asia, and have been recognized by customers at home and abroad. HY can produce according to national technical standards according to customer needs. All performance indicators meet national standards and can provide complete qualification certification documents. Providing customers with high-quality, cost-effective products and excellent after-sales service is our mission and commitment to customers.

Product type: solar mounting system, ground mount solar

Processing services: stamping, die-casting, bending, welding, punching, cutting

Thickness: 0.5-3.0mm or customer requirements

Length: 1m-12m or customer requirements