- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China metal lid Manufacturers, Suppliers, Factory

Our goal is to satisfy our customers by offering golden service, good price and high quality for metal lid,stainless steel metal lid,metal pan lids,steel lids,Stamped stainless steel metal lid, Our products are strictly inspected before exporting , So we gain a good reputation all over the world. We looking forward to cooperation with you in the future.

metal lid, When you are keen on any of our items following you view our product list, please feel free to make contact with us for inquiries. You'll be able to send us emails and get in touch with us for consultation and we shall respond for you as soon as we are able to. If it's convenient, you could find out our address in our web site and come to our enterprise. or additional information of our goods by yourself. We're generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

Hot Products

Spark Plug

Xiamen Hongyu Intelligent Technology Co., Ltd. is a leading and well-known manufacturer of high-end automotive engine spark plugs. Its electrodes are made of high-quality metal iridium and platinum, suitable for various cars, such as CORROLA, RAV4, CAMRY, TOYOTA VOIS, ALPHA car engines. Our spark plugs are made of high-quality raw materials and have excellent engine performance.

Main products: double iridium, double platinum, iridium platinum, single iridium, single platinum, nickel, CNG, LPG special vehicle high-end spark plugs

Electrode material: iridium

OEM customization: supportportable handicap ramp

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional aluminum alloy manufacturer. The company has its own independent technical research and development capabilities, perfect manufacturing processes and sound quality control systems. It specializes in providing portable handicap ramp for residential and commercial places, and provides customized barrier-free solutions for people with limited mobility. It covers an area of 4,500 square meters and supplies more than 15 tons of raw materials per month. HY has obtained a number of Chinese utility model patents, appearance patents, EU appearance patents, CE safety certification, ISO9001:2015 and ISO13485 certificates.

Our main products are divided into two categories:

1. Barrier-free medical rehabilitation aids: crutches, bathing chairs, commode chairs, walkers, etc.

2. Aluminum alloy barrier-free ramps: folding ramps, rolling circular ramps, portable disabled ramps, etc.machine screws

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of machine screws fasteners, focusing on different series of fastener products, including stainless steel and carbon steel nuts, screws, bolts, washers and various stamping and die-casting products. Based on our own production capacity, we can provide one-stop product services such as design, customization, production and after-sales according to your needs.

Thread size: M6/M8//M10/M12/M14/M16/More

Surface treatment: galvanized/other

Material: stainless steel

Standard: ISO8677, DIN603, GB14Stainless Steel Quick Connect

Product Name:Stainless Steel Quick Connect

Material: 304, 316, 201, 430

Proofing Cycle: 4-7 days

Molding Process: Gravity Casting

Certification: ISO9001:2015

Surface Treatment: Polishing, Brushing, Electroplating, Powder Spraying, Electrophoresis, Sandblasting, Spray Paintingangle bracket

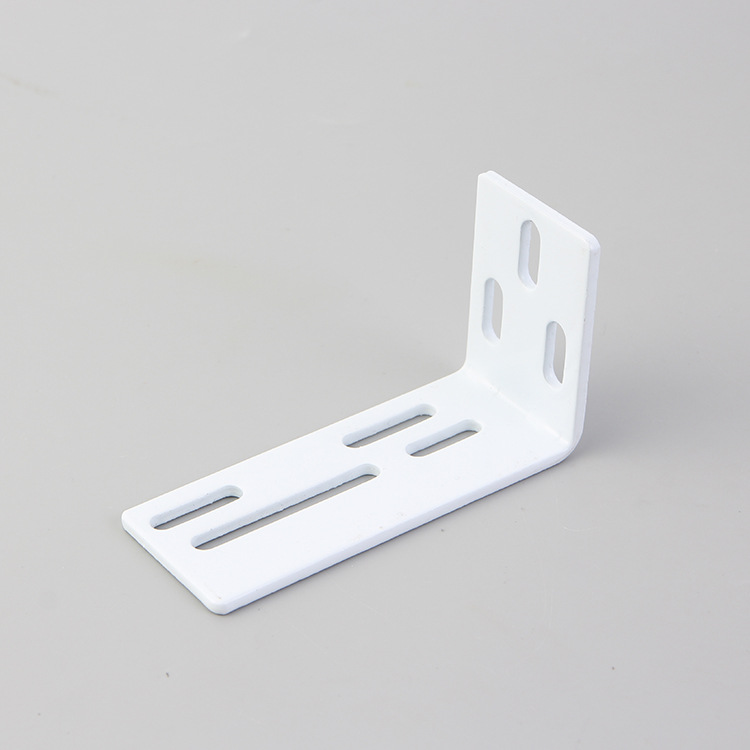

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company specializing in the manufacture of various metal stamping parts and sheet metal. HY has focused on the research and improvement of relevant technologies and management levels for many years, providing non-standard customized services on high-end hardware products, such as customized whole machines, laser cutting parts, aluminum stamping, meter boxes, OEM metal boxes, angle brackets, etc. For stamping business, HY can design and manufacture new molds and respond to changes at a very fast speed, and can provide solutions for various difficult metal stamping parts.

Product Type: Angle Bracket, Corner Bracket

Surface Treatment: Galvanizing, Anodizing, Chrome Plating, Powder Plating

OEM/ODM: Support customization

Processing Technology: Mold, Stamping, Surface Treatment, Welding and AssemblyHair Dryer Filter

Xiamen Hongyu Intelligent Technology Co., Ltd. has 17 years of processing and manufacturing experience and has been providing high-quality Hair Dryer Filter to customers at home and abroad. The filter hair dryer we produce is light in weight, has good stability, and has good anti-oxidation filtration. It can effectively use manufacturing processes such as stamping and etching to save materials and reduce production costs. Material: 304 stainless steel, aluminum alloy, titanium, nickel-based alloy, etc. Specifications: Customizable Use scenarios: home, hotel, barber shop, etc.