- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Exhaust pipe suppliers Manufacturers, Suppliers, Factory

Our mission is to become an innovative supplier of high-tech digital and communication devices by providing value added design, world-class manufacturing, and service capabilities for Exhaust pipe suppliers,bronco exhaust,exhaust systems,catalytic converter replacement,stainless exhaust tubing, We hope to establish far more organization associations with consumers all over the globe.

Exhaust pipe suppliers, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to offer you good quality products and the best service. We are looking forward to serving you.

Hot Products

Car Rims

Xiamen Hongyu Intelligent Technology Co., Ltd. is a comprehensive enterprise integrating design, R&D, manufacturing, sales and after-sales service. The main products include original wheels, modified wheels, car rims, off-road wheels, racing wheels, etc. The wheels are available in multiple specifications and sizes from 13 inches to 26 inches, supporting personalized forging and customization by customers.

Wheel structure: integral

Wheel diameter: 13 inches, 18 inches, support customization

Material: aluminum alloy

Applicable models: Tank 300, Wrangler, Great Wall, Tesla, BMWEngine Turbocharger

Xiamen Hongyu Intelligent Technology Co., Ltd. produces Engine Turbocharger with low price and good quality. It is a well-known domestic die-casting manufacturer. HY has a professional engineering design team and supports customized services. It can design solutions and complete the final product according to the customer's drawings or ideas.

Turbocharger molding process: high pressure casting

Surface treatment: polishing oxidation

Material: aluminum alloy

Tolerance: 0.2

Proofing cycle: 4-7 days

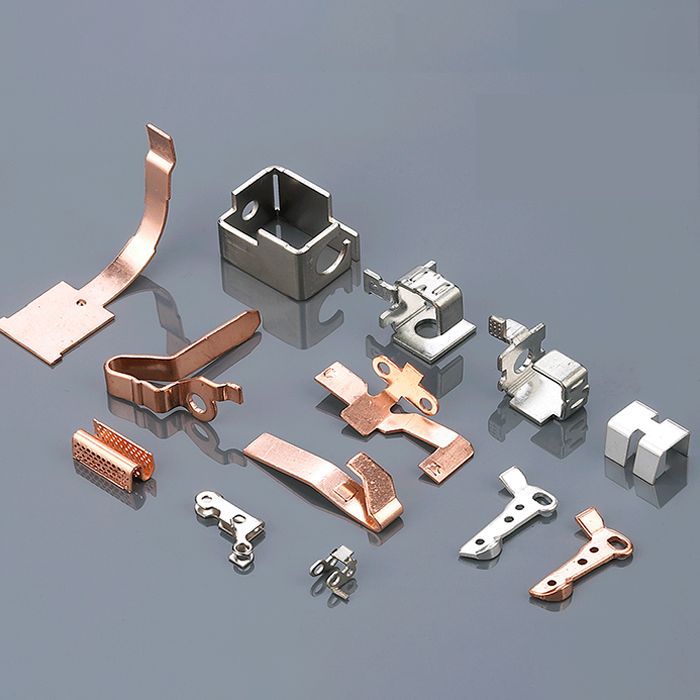

Processing cycle: 8-15 daysSelective Plated Terminals

HY is a factory that Selective Plated Terminals progressive high-speed stamping dies.OEM metal progressive high speed stamping die for selective plated terminals part/press machine/electrical jack metal part/electrical appliance metal hook buckle。Metal Stamping Automotive Catalytic Converter

HY is China manufacturer & supplier who mainly produces Metal Stamping Automotive Catalytic Converter with many years of experience. Hope to build business relationship with you.Metal Medical Stamping

HY is a well-known manufacturer of Metal Medical Stamping in China. Nearly 20 years of experience in manufacturing stamped medical parts.HY is a well-known manufacturer of stamped metal medical parts in China.Casting Gearbox Components

Hongyu Intelligent specializes in die-casting many important transmission components for the automotive and heavy-duty Casting Gearbox Components Manufacturing stamping industry.