- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China drone propellers Manufacturers, Suppliers, Factory

To be a result of ours specialty and repair consciousness, our corporation has won a good popularity amid consumers everywhere in the environment for drone propellers,Bearing Carrier Propeller,propeller,master airscrew propellers,Die cast propeller manufacturer, We warmly welcome prospects, organization associations and mates from everywhere in the earth to get in touch with us and request cooperation for mutual benefits.

drone propellers, By continuous innovation, we will supply you with more valuable merchandise and services, and also make a contribution for the development of the automobile industry at home and abroad. Both domestic and foreign merchants are strongly welcomed to join us to grow together.

Hot Products

Metal Stamping Fasteners

HY improve and design industrial fasteners by Metal Stamping Fasteners, providing lower-cost precision metal stamping parts, and more efficient alternative solutions. Metal stampings are commonly used in nearly every industry, including electrical, automotive, appliances, and construction.crutch

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturing factory that produces various wheelchairs, commode chairs, shower chairs, crutch, walkers and other medical rehabilitation products. With more than 17 years of processing and manufacturing experience, our factory has passed IS013485 and IS09001 quality management, and the products have passed CE certification.

Product type: crutch

Use: medical rehabilitation supplies

Color: matte, metallic, silverMedical Equipment Base

You can purchase Medical Equipment Base from HY with confidence, as we are a proficient producer of high-quality Medical Equipment Base. We promise to provide you with the best after-sale service and prompt delivery.

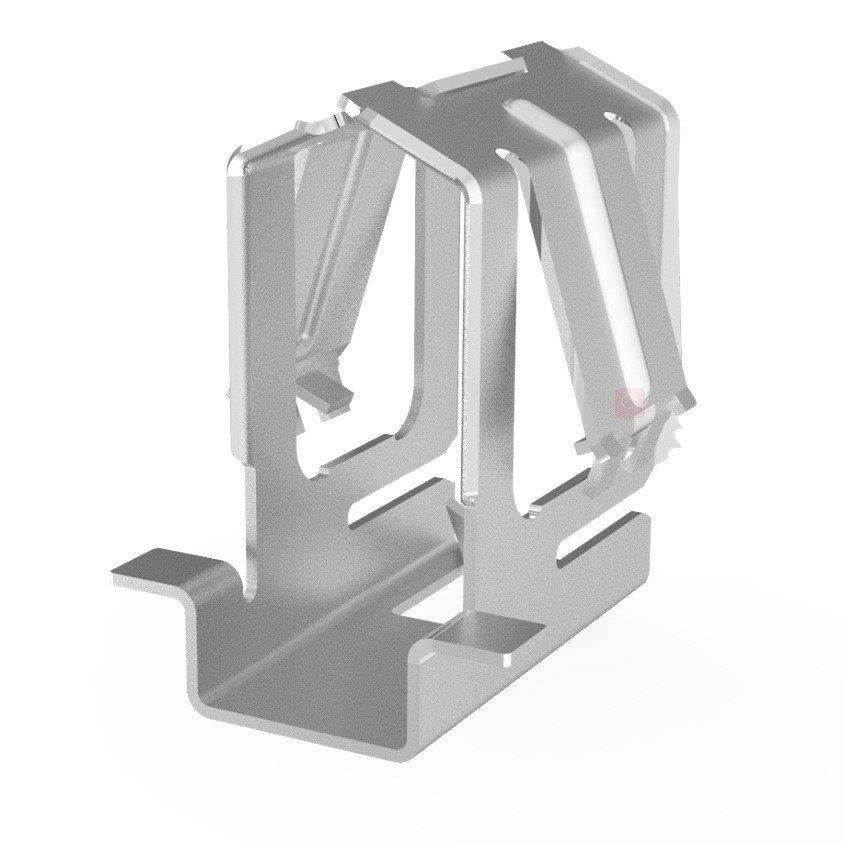

Product name: Precision sheet metal base for medical equipment

Material: Material thickness electrolytic plate

Surface treatment: electroplating anodizing

Product size: non-standard customization, customization according to drawings

Processing technology: sheet metal stamping, laser cutting, bending and riveting applications

Application areas: medical equipment automation equipmentmetal phone cases

Xiamen Hongyu Intelligent Technology Co., Ltd. is an integrated factory of industry and trade. We support the production and customization of metal phone cases. You can provide samples or drawings of metal phone cases. HY has professional mechanical processing and system testing service processes. HY has a complete production line to ensure that it can meet the monthly production capacity needs and provide one-stop services, covering furniture accessories, electronic accessories, medical equipment accessories and other fields. HY is confident to establish long-term cooperation to provide customers with competitive solutions.

ODM service time: It can be completed in 3-5 days at the fastest.

Drawing design service: Support customized design service.

Quality certificate: ISO 9001, ISO14001, REACH, RoHs

Tolerance: 0.02shower chair for disabled

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturing company specializing in the production and sales of bathroom and medical care series products, with more than 17 years of processing experience. HY is proficient in global standards, focusing on the production of high-quality products, with a strict process system and quality inspection system to ensure product quality and delivery time. It has now covered the United States, Europe, Australia, the Middle East and other countries. We welcome global customers to establish cooperation.

Color: Black/Silver/White/Gray/Customized

Usage: Shower chair for disabled

Material: High-quality PE and thickened aluminum alloy pipe

Application scenarios: Bathroom, Hospital, OtherDie Casting Bearing Carrier Propeller

HY is a stamping manufacturing factory from China.A die casting bearing carrier propellerr in which two or more blades are connected to the hub, and the blade surface is a helical surface or an approximate helical surface.