- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Die Casting Fitting Supplier Manufacturers, Suppliers, Factory

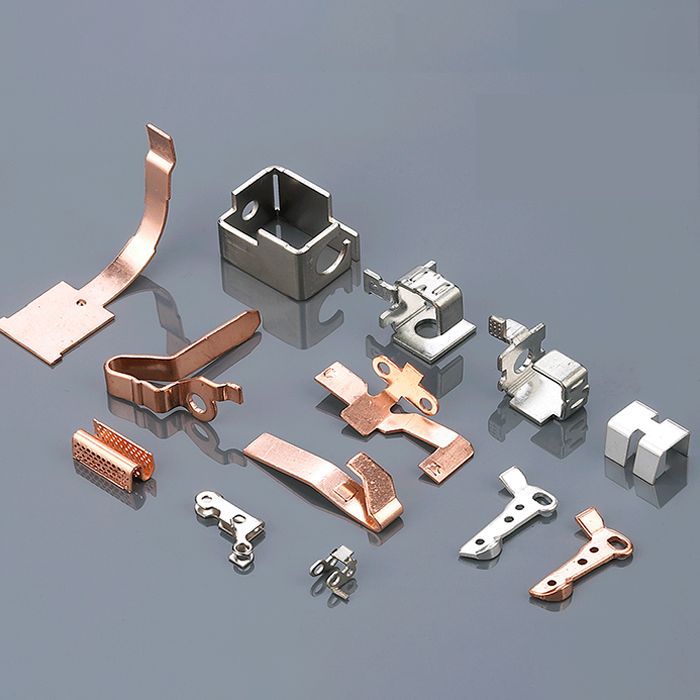

Bear "Customer very first, Quality first" in mind, we work closely with our customers and supply them with efficient and professional services for Die Casting Fitting Supplier,metal bellows expansion joints,stainless steel bellows expansion joint,Die Casting,Aluminum Die Casting, If you're interested in any of our products and services, make sure you don't be reluctant to call us. We've been wanting to reply you within 24 several hours just after receipt of your respective ask for and to generate mutual un-limited positive aspects and enterprise in in the vicinity of long run.

Die Casting Fitting Supplier, We have been always creating new technology to streamline the production, and offer goods with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We'll offer you our best service to satisfy all your needs! Be sure to contact us right away!

Hot Products

Paint Spoon

Product name: Hardware stamping paint spoon

Material: carbon steel plate

Mold: multi-process continuous mold

Processing size: 66.3*34*10 (mm)

Process: cutting, forming, deep drawing, cold extrusionInconel Part Oil Stamping

HY is a manufacturer and seller of custom Inconel Part Oil Stamping, Inconel part stampings are used in the petroleum industry and are very popular.Transmission Lead-Frames

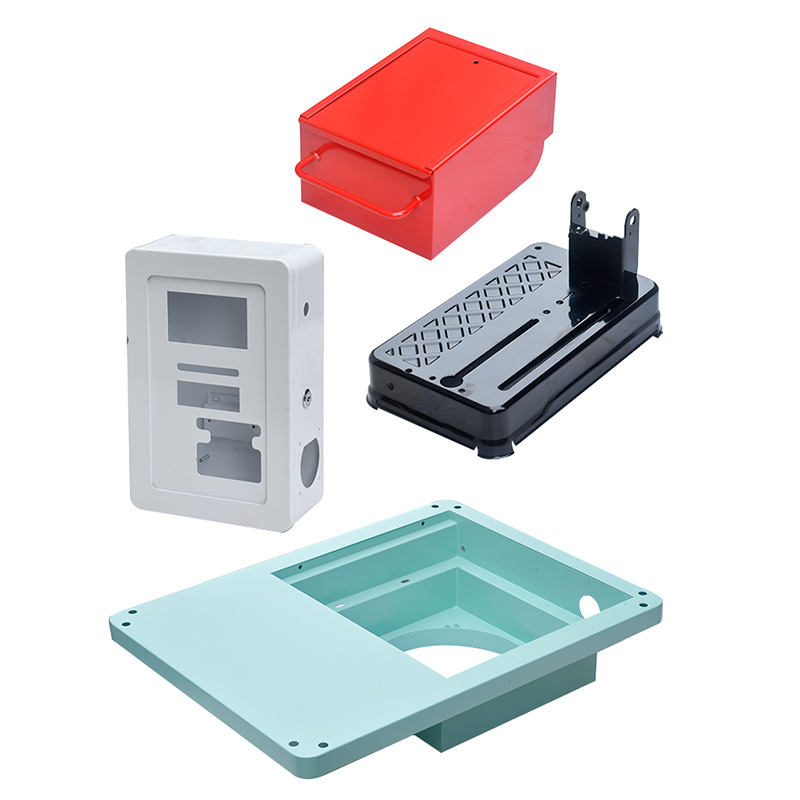

HY is a professional Transmission Lead-Frames manufacturers and suppliers in China, If you manufacture rice cookers, dryers, refrigerators, and other appliances, you rely on small components such as transmission lead frames manufactured by the best appliance stampings suppliers. This is where HY Corporation can help.Motor Housing

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company specializing in the production of motor housing. HY is a professional manufacturer specializing in metal stamping, metal castings and backlog parts. Today, we have developed into a comprehensive group, providing one-stop services for production, sales and after-sales. HY always puts the quality of motor housing products first and strictly implements ISO9001 and ISO14001:2004 system standards, which enables us to keep pace with international standards.

Product type: motor housing, aluminum motor housing

Surface treatment: anodizing, sandblasting, support customization

Drawing format: AutoCAD, Solidworks, CAXA, UG, CADDie Casting Pump Body

Hongyu is a factory specializing in the production of die casting pumps. A pump is a mechanical device that moves fluid (liquid or gas, slurry). Die casting pump body is the process of designing and casting pump parts from aluminum alloy. It can provide products with higher strength and corrosion resistance and handle liquid substances.solar mounting system

Xiamen Hongyu Intelligent Technology Co., Ltd. is a high-tech enterprise specializing in the research and development, production, sales and service of solar photovoltaic support systems in the new energy industry. These products have been sold to more than 100 countries and regions including the United States, the European Union, Australia, the Middle East, South Africa, Japan and Southeast Asia, and have been recognized by customers at home and abroad. HY can produce according to national technical standards according to customer needs. All performance indicators meet national standards and can provide complete qualification certification documents. Providing customers with high-quality, cost-effective products and excellent after-sales service is our mission and commitment to customers.

Product type: solar mounting system, ground mount solar

Processing services: stamping, die-casting, bending, welding, punching, cutting

Thickness: 0.5-3.0mm or customer requirements

Length: 1m-12m or customer requirements