- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Aluminum Light housing Manufacturers, Suppliers, Factory

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for Aluminum Light housing,casting aluminum,aluminum die casting manufacturer,die cast metal,aluminum die casting, Our final goal is "To try the best, To be the Best". Please feel free to contact with us if you have any requirements.

Aluminum Light housing, We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!

Hot Products

Selective Plated Terminals

HY is a factory that Selective Plated Terminals progressive high-speed stamping dies.OEM metal progressive high speed stamping die for selective plated terminals part/press machine/electrical jack metal part/electrical appliance metal hook buckle。Uv Nail Lamp Metal Shell

Xiamen Hongyu Intelligent Technology Co., Ltd. is one of the manufacturers specializing in the production of high-quality Uv Nail Lamp Metal Shell. You can rest assured to buy uv nail lamp metal shell from HY. We will provide you with the best after-sales service and timely delivery.

Product name: LED Nail Lamp shell

Surface treatment: sandblasting

Material: aluminum alloy

Feel: anti-fall, wear-resistant, not easy to break, smooth and texturedPerfume Cap

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturer specializing in the production of high-quality perfume bottle caps. We provide high-quality caps for perfume bottles to customers at home and abroad. We will provide you with the best after-sales service and timely delivery.

Product name: Perfume cap

Special casting types:Metal mold casting

Surface treatment: electroplating

Material: zinc alloy

Molding process: gravity die casting

Tolerance: 0.02

Proofing cycle: 1-3 daysEnergy Vehicle Charging Gun Housing

HY is a manufacturer and supplier of Energy Vehicle Charging Gun Housing. HY precision metal stamping mold new energy vehicle charging gun stamping parts specifications: 1. The material is phosphor bronze C5191. Material thickness is 0.3mm. 2. Support surface treatment: silver plating, gold plating, nickel plating or chrome plating. 3. The seams of the stamped parts are tightly combined, without deformation, overlap, or gaps. In the drop test from a height of 2 meters in any direction, the components were not damaged.screw washer

Xiamen Hongyu Intelligent Technology Co., Ltd., has three steel hardware manufacturing plants and a 3,000 square meter logistics warehouse. HY is specialized in building stampings, fasteners and automotive parts. We produce and supply a whole range of screws,screw washer, nails, bolts, nuts, threaded rods, anchors, couplers, stampings, connectors, plastic parts, pipes, chains, etc. Our products meet international quality standards such as DIN, BS, ANSI, JIS, etc.

Material: Carbon Steel

Surface Treatment: Galvanized

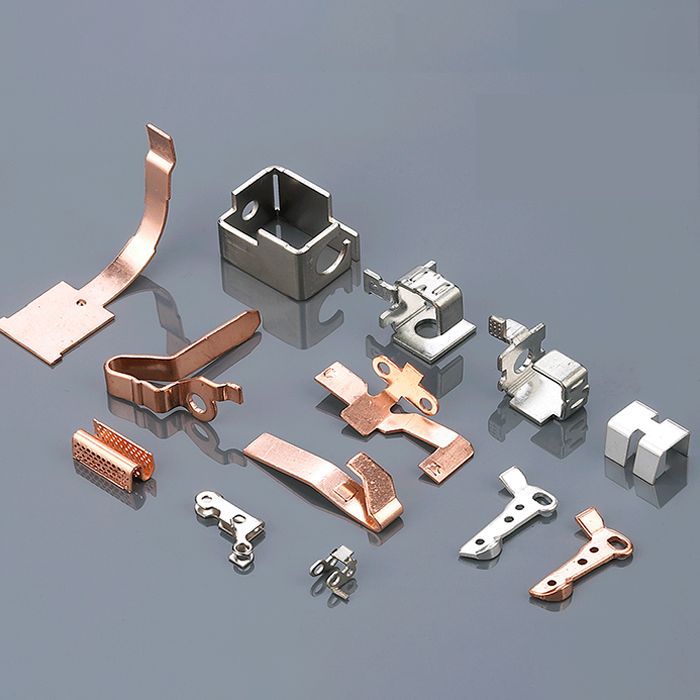

Size: Metric, Imperialmetal stamping small parts

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional stamping parts manufacturer. The metal stamping small parts produced by HY are widely used and suitable for stamping, shearing, forming, stretching, bending and other multi-purpose processing of metal sheets in large quantities. Product name: metal stamping small parts Customization: Customization is supported Material support: stainless steel, aluminum, copper, titanium alloy, etc. Drawing format: Stp, Step, Igs, Xt, AutoCAD (DXF, DWG), PDF or sample