- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Metal die casting Manufacturers, Suppliers, Factory

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Metal die casting,Die casting factory,Lighting Accessories,flashlight lighting,Aluminum Die Casting, By more than 8 years of company, now we have accumulated rich experience and advanced technologies from the generation of our merchandise.

Metal die casting, we're now looking forward to even greater cooperation with overseas customers based on mutual benefits. We'll work wholeheartedly to improve our merchandise and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

Hot Products

machine screws

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of machine screws fasteners, focusing on different series of fastener products, including stainless steel and carbon steel nuts, screws, bolts, washers and various stamping and die-casting products. Based on our own production capacity, we can provide one-stop product services such as design, customization, production and after-sales according to your needs.

Thread size: M6/M8//M10/M12/M14/M16/More

Surface treatment: galvanized/other

Material: stainless steel

Standard: ISO8677, DIN603, GB14Die Casting Automotive Filter

Die Casting Automotive Filter,HY has extensive experience helping Chinese automakers with prototyping, designing and manufacturing aluminum and zinc alloy die castings.Stamping Wire Formed Fasteners

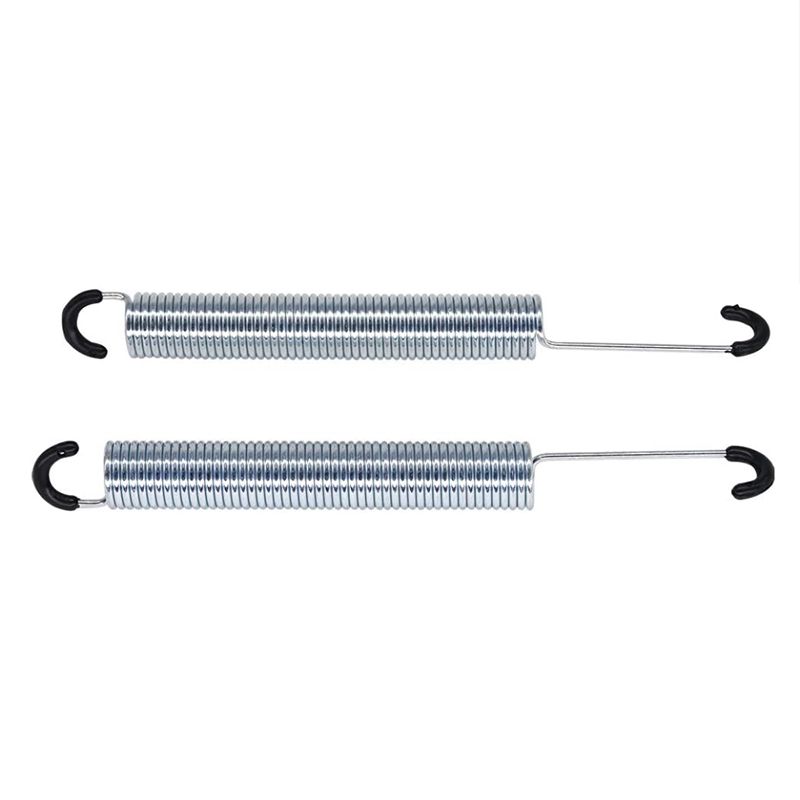

HY is a factory that Stamping Wire Formed Fasteners wire formed fasteners .Wire forming is the process of shaping metal wire into useful parts such as springs, wire formed fasteners and retaining rings.spring washers

Xiamen Hongyu Intelligent Technology Co., Ltd. is a leading manufacturer and supplier of spring washers fasteners. Over the years, we have served many customers in North America, Europe, Oceania and the Middle East, and our quality and fast delivery have been praised by many customers. HY has passed IS09001:2015 international quality management system certification, IATF16949:2016 automotive industry quality management system certification and IS014001:2015 environmental management system certification.

Application scenarios: mining, healthcare, retail industry, industrial machinery, oil and gas, automotive industry

Product type: belleville washer/spring washers

Surface treatment: black, galvanized, other customization

Material: stainless steel, aluminum, special requirements

Processing technology: stampingMetal Stamping Automotive Catalytic Converter

HY is China manufacturer & supplier who mainly produces Metal Stamping Automotive Catalytic Converter with many years of experience. Hope to build business relationship with you.crutch

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturing factory that produces various wheelchairs, commode chairs, shower chairs, crutch, walkers and other medical rehabilitation products. With more than 17 years of processing and manufacturing experience, our factory has passed IS013485 and IS09001 quality management, and the products have passed CE certification.

Product type: crutch

Use: medical rehabilitation supplies

Color: matte, metallic, silver