- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China engine accessory gearbox Manufacturers, Suppliers, Factory

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for engine accessory gearbox,wind turbine gearbox types,worm gearbox parts,automatic gearbox parts,Die cast auto parts, Presently, we are looking forward to even larger cooperation with overseas clients based on mutual benefits. Make sure you come to feel no cost to make contact with us for more information.

engine accessory gearbox, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

Hot Products

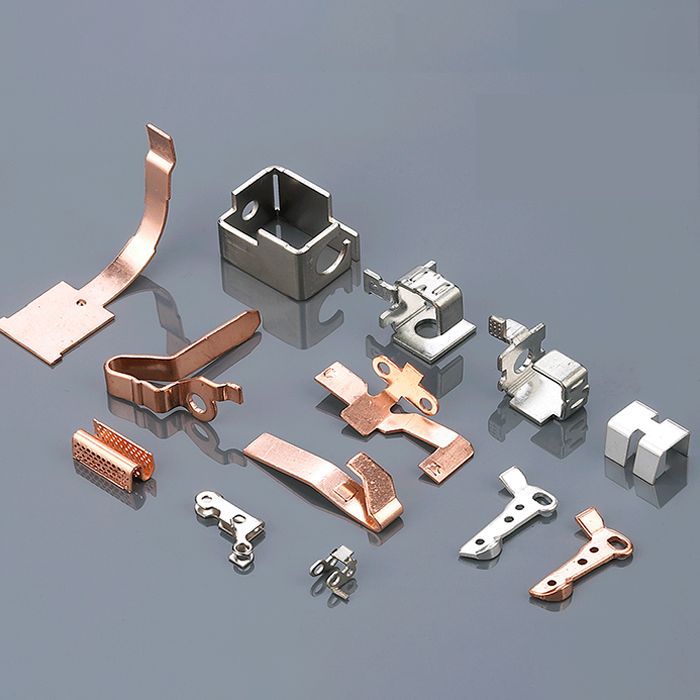

Selective Plated Terminals

HY is a factory that Selective Plated Terminals progressive high-speed stamping dies.OEM metal progressive high speed stamping die for selective plated terminals part/press machine/electrical jack metal part/electrical appliance metal hook buckle。stroller frame for car seat

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company that designs, develops, produces, sells and provides after-sales services. As an exporter of Chinese baby-related industries, it has exported stroller frames for car seats to more than 20 countries around the world. HY has always taken design, research and development and strong after-sales services as the core of our strategy, strictly controlling each product to ensure the customer's after-sales experience. HY welcomes global customers to discuss cooperation.

Type: Stroller frame for car seat

Fabric: Oxford cloth, high-grade leather, etc.

Material: Aluminum alloy, high carbon steel, special alloys support customization

Application scenarios: outdoor/home/camping/multi-purpose passenger cars/RVs/family cars, etc.

Processing technology: metal die-castingCasting Exhaust Systems

Stainless steel Casting Investment Casting exhaust systems pipe Services, Precision Casting Parts. The exhaust system produced by Hongyu Intelligent Technology has the following advantages: 1.The inner wall is smooth and the exhaust resistance is low; 2.The heat transfer is fast, which is conducive to the rapid ignition of the close-coupled three-way catalyst and the purification of exhaust gas; 3.Lighter weight;Car Differential

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturer specializing in the production of automotive parts for heavy and light vehicles at home and abroad. Including drive axles, suspension components, gearboxes, Car Differential and other products. HY In order to ensure product quality, we have imported advanced production equipment and testing equipment, including American HASS lathes, Japanese FANUC manipulators, three-dimensional coordinate measuring machines, etc. We welcome inquiries and feedback from customers at home and abroad.

Application range: automotive transmission, industrial machinery

Surface treatment: carbonization, sandblasting, can be customized according to customer needs

Processing technology: die castingMedical Equipment Base

You can purchase Medical Equipment Base from HY with confidence, as we are a proficient producer of high-quality Medical Equipment Base. We promise to provide you with the best after-sale service and prompt delivery.

Product name: Precision sheet metal base for medical equipment

Material: Material thickness electrolytic plate

Surface treatment: electroplating anodizing

Product size: non-standard customization, customization according to drawings

Processing technology: sheet metal stamping, laser cutting, bending and riveting applications

Application areas: medical equipment automation equipmentMetal Stamping Electronic Wire Assemblies

HY is a Metal Stamping Electronic Wire Assemblies factory that custom-processes metal stamped electronic wire assemblies.The industries served by HY include home appliances, electrical equipment, electronics, and lighting. Nearly 20 years of experience in Precision Metal Stamping.