- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

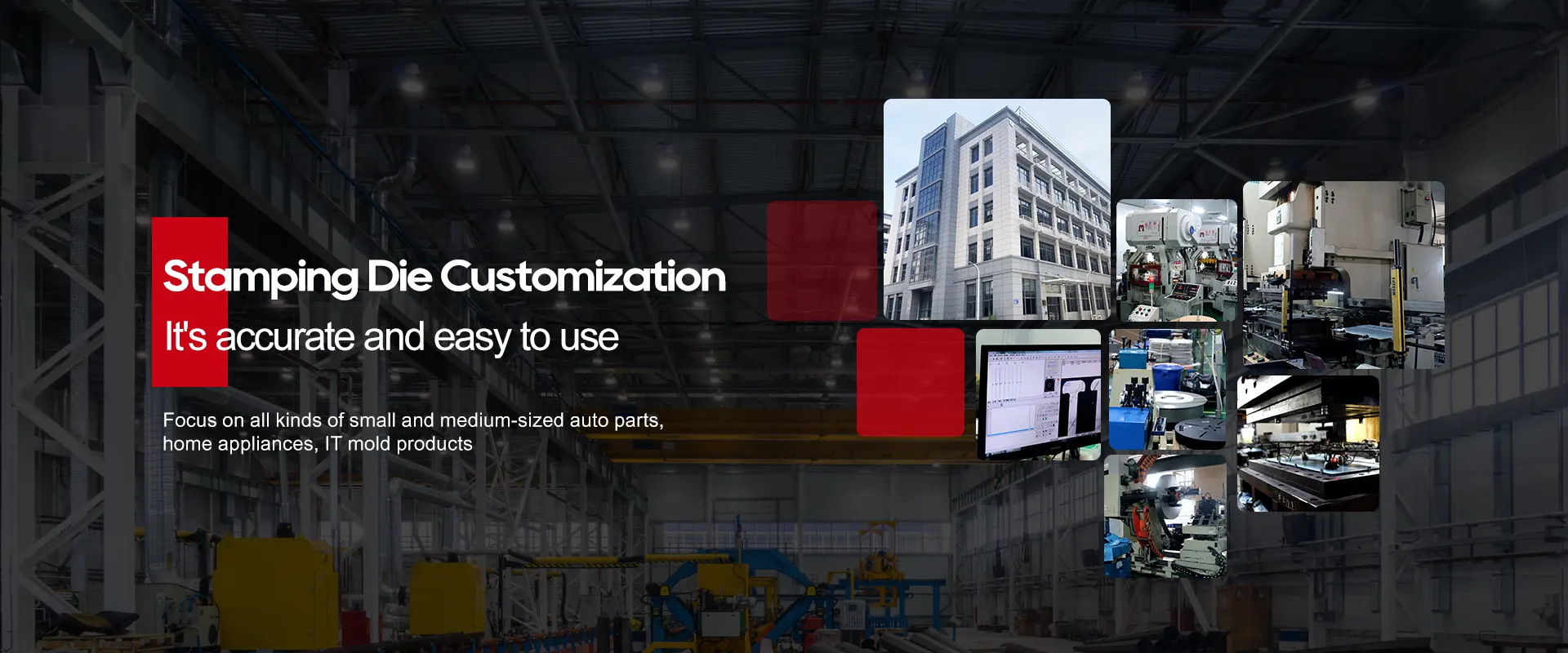

More than 20 years of industry experience and technology

Metal stamping services and precision stamping dies

Strict Quality Control

Need high-quality parts? With our advanced equipment and well-established process control techniques, we produce great results for our customers. Our in-house QC team and technicians work hard to ensure that each and every job gets done right.

Quick Turnaround Time

Need to get your products to market fast? We specialize in rapid prototyping and rapid tooling and we know how to make the process feel effortless. We’ll meet your high standards for quality and ensure that your products are delivered to you on time.

Global Delivery

Need a manufacturer with deep experience in international markets? For 10+ years, we’ve been working with customers all over the globe. We understand international shipping and logistics and will deliver your high-quality parts right to your door.

Xiamen Hongyu Intelligent Technology Co., LTD

Established in October 2007, Xiamen Hongyu Intelligent Technology Co., Ltd. provides mass production metal stamping services and R&D and production of precision stamping dies, such as progressive die high-speed stamping, progressive die heavy metal stamping, engineering support, in-house tool manufacturing, rapid Prototyping, water jet cutting and automated assembly of parts. The products involve stamping and die castings in various fields such as automobiles, communications, photovoltaic new energy, aviation, medical electronics, smart home appliances, IC, and 3C products. The company is located in Xiamen City, a paradise on earth, surrounded by Baoshan and the sea, covering an area of 2,000 square meters, with more than 200 employees. It has 30 high-speed punching machines imported from Japan, 40 CNC machining centers, western and Mitsubishi slow wire walking, spark discharge, forming grinding, large surface grinding machines, cutting machines, hydraulic shearing machines, precision grinding machines, digital display milling machines, radial drilling machines, CNC machining centers, CNC lathes, welding robots and other high-end processing equipment. With an annual output of 20,000 tons of aluminum alloy parts R & D, production and precision processing capabilities, to achieve the effect of large-scale production. Over the years, the company has led production with technology, positioned "high quality", and focused on product quality and research and development. It has a number of patents and innovative processes in the fields of new technology and precision numerical control processing technology. Products are exported to Europe, America, Middle East, and Asian markets. In terms of quality, environment, management and safety, Hongyu has successively passed ISO9001, TS16949 and ISO14001 system certifications, fully guaranteeing the stability and consistency of product quality.

Contact Us-

20+

Years of experience

-

200+

Company Employee

-

2000+

Plant Area

-

20000+

Annual output value

CORE MANUFACTURING SERVICES

Metal Stamping

Focus on the research and development of precision stamping parts, rich experience, strong technology

Die Casting

Perfect casting process and exquisite product design, in line with industry requirements

Casting Parts

Has a strong technical team, can be customized, to provide a total solution

Featured Products

Drawer Slides

Xiamen Hongyu Intelligent Technology Co., Ltd. is a factory and manufacturer specializing in the production of drawer slides, hinges, bed hinges, corner brackets, and more. Our cabinet drawer slides are renowned for their superior quality and craftsmanship. We specialize in innovative development and custom manufacturing, supporting customized production tailored to individual customer needs. HY currently utilizes automated stamping, welding, and painting processes, ensuring stable and reliable craftsmanship and quality while guaranteeing production efficiency. Our products are trusted by customers in Europe, America, Russia, the Middle East, and other regions.

Surface Finishes: Galvanized, Black, Silver

Applications: Furniture, Kitchen Cabinets, Office Cabinets, Bathroom Cabinets, and Wooden Furniture

Mixing Valve

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of mixing valves, filters, pipes, valves, connectors and other related accessories. HY focuses on developing new products. We can also provide OEM services according to customer drawings.

Material: brass, aluminum alloy, zinc alloy, magnesium alloy

Customized service: support

Diameter: 1/2, 3/4, 1 inch

Motor Housing

Xiamen Hongyu Intelligent Technology Co., Ltd. is a high-tech die-casting company specializing in the production of motor housing. From design to mold sample production, HY currently serves more than 50 industries, including automotive parts, consumer electronics, hardware tools, smart home and other industries.

Product type: motor housing, aluminum motor housing

Surface treatment: anodizing, sandblasting, support customization

Drawing format: AutoCAD, Solidworks, CAXA, UG, CAD

metal phone cases

Xiamen Hongyu Intelligent Technology Co., Ltd. is an integrated factory of industry and trade. We support the production and customization of metal phone cases. You can provide samples or drawings of metal phone cases. HY has professional mechanical processing and system testing service processes. HY has a complete production line to ensure that it can meet the monthly production capacity needs and provide one-stop services, covering furniture accessories, electronic accessories, medical equipment accessories and other fields. HY is confident to establish long-term cooperation to provide customers with competitive solutions.

ODM service time: It can be completed in 3-5 days at the fastest.

Drawing design service: Support customized design service.

Quality certificate: ISO 9001, ISO14001, REACH, RoHs

Tolerance: 0.02

photovoltaic inverter

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional stamping manufacturer specializing in photovoltaic inverters. Our products are suitable for residential, commercial, and industrial applications, and we support customized services, providing customers with market access and reliability guarantees. HY has a professional and experienced engineering design team that can turn your ideas into reality, providing customers with one-stop solutions.

Protection level: IP67

Type: pv inverter, solar and power inverter

Size: Customization supported

Material: aluminum, metal, stainless steel, aluminum alloy, galvanized steel

lunch box

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of stamped lunch boxes, covering a wide range of products including kitchen furniture, bento boxes, water cups, and baby products. Adhering to the principles of quality first and integrity in business, the company integrates production, processing, and independent sales, and its prices and quality have gained industry recognition.

Type: lunch box, kids lunch box, stainless steel lunch box

Material: 304/316 food grade stainless steel

Customization: support OEM/ODM customization

shutters

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturing enterprise specializing in shutters. With over ten years of experience in manufacturing aluminum alloy doors and windows and metal shutters, HY offers a wide range of product styles. Customization and material selection can be made based on the climatic characteristics of different regions and customer requirements, which is crucial to the durability and functionality of the windows.

Types: metal shutters, aluminum window shutters, steel shutters

Customization service: support OEM/ODM customization

Application scenarios: home, hotel, B&B, factory, ventilation

Auto Battery Tray

Xiamen Hongyu Intelligent Technology Co., Ltd. is a production-oriented enterprise specializing in the manufacturing of auto battery trays. It is an integrated company that combines design, manufacturing, sales and after-sales service. HY has over 5,000 square meters of factory space and more than 120 employees, mainly engaged in the design and production of Toyota Prado battery trays through stamping and die-casting processes.

Process: aluminum stamping, aluminum extrusion, precision machining, welding assembly

Surface treatment: spraying, black, galvanizing

Application scenarios: automobiles, electric vehicles, ships, etc.

Battery Trays

Xiamen Hongyu Intelligent Technology Co., Ltd. is a production-oriented enterprise specializing in the manufacture of battery trays. It is committed to providing customers with high-quality solutions. The company holds multiple qualifications and patents and always prioritizes customer service and product quality. The car battery holders produced by HY come in various shapes and standards and can offer customized services for different vehicle models based on customer requirements.

Process: casting, precision machining, welding assembly

Surface treatment: pre-galvanizing, passivation

Model: customized

portable handicap ramp

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional aluminum alloy manufacturer. The company has its own independent technical research and development capabilities, perfect manufacturing processes and sound quality control systems. It specializes in providing portable handicap ramp for residential and commercial places, and provides customized barrier-free solutions for people with limited mobility. It covers an area of 4,500 square meters and supplies more than 15 tons of raw materials per month. HY has obtained a number of Chinese utility model patents, appearance patents, EU appearance patents, CE safety certification, ISO9001:2015 and ISO13485 certificates.

Our main products are divided into two categories:

1. Barrier-free medical rehabilitation aids: crutches, bathing chairs, commode chairs, walkers, etc.

2. Aluminum alloy barrier-free ramps: folding ramps, rolling circular ramps, portable disabled ramps, etc.

Uv Nail Lamp Metal Shell

Xiamen Hongyu Intelligent Technology Co., Ltd. is one of the manufacturers specializing in the production of high-quality Uv Nail Lamp Metal Shell. You can rest assured to buy uv nail lamp metal shell from HY. We will provide you with the best after-sales service and timely delivery.

Product name: LED Nail Lamp shell

Surface treatment: sandblasting

Material: aluminum alloy

Feel: anti-fall, wear-resistant, not easy to break, smooth and textured

Perfume Cap

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturer specializing in the production of high-quality perfume bottle caps. We provide high-quality caps for perfume bottles to customers at home and abroad. We will provide you with the best after-sales service and timely delivery.

Product name: Perfume cap

Special casting types:Metal mold casting

Surface treatment: electroplating

Material: zinc alloy

Molding process: gravity die casting

Tolerance: 0.02

Proofing cycle: 1-3 days

Stamp your precision machined parts, produced using state-of-the-art stamping machines

Precision machining and stamping services

Let us turn your product designs or ideas into reality with top-notch precision stamping hardware services. We offer stamping services to companies that want custom, one-of-a-kind designs in a variety of metals.

Using HY's state-of-the-art hydraulic punch press, a team of experienced engineers and first-class technicians can produce finished products in the fastest possible time. HY also has a dedicated quality inspection department to test and ensure that all precision metal stamping parts meet customer requirements.

Whether it's a small precision electronic brass part or a large automotive housing, our custom stamping services can provide a comprehensive and satisfying solution to your product development project.

What is precision metal stamping?

Precision metal stamping is a high-volume metalworking process that uses stamping tools to create sheet metal parts by stamping the material into the desired shape. This is done according to a pattern and each part is removed from the motherboard after stamping.

Precision metal stamping methods allow manufacturers to create parts that require undercuts, multiple features or fragile walls for assembly.

It uses high-pressure equipment to press metal sheets into molds, so the product's shape has geometric precision and an excellent surface finish.

What are the complete stamping processes of HY?

Blanking: The stamping process that separates sheets (including punching, blanking, trimming, sectioning, etc.).

Bending: The stamping process of bending sheet metal into a certain angle and shape along the bending line.

Deep drawing: A stamping process that turns flat sheets into various open hollow parts, or further changes the shape and size of hollow parts.

Local forming: a stamping process that uses various local deformations of different properties to change the shape of the blank or stamping part (including flanging, bulging, leveling and shaping processes, etc.).

Why choose precision metal stamping to produce parts?

1. Precision metal stamping can improve production efficiency, reduce costs, and is suitable for mass production needs.

2. Precision metal stamping can ensure the dimensional accuracy, stable quality, and good interchangeability of parts, reducing subsequent inspection and repair work.

3. Precision metal stamping can make the surface quality of parts better, which facilitates subsequent surface treatment (such as electroplating, painting, etc.).

4. Precision metal stamping can obtain parts with small size, light weight and high stiffness while saving materials, which improves the performance and service life of the parts.

To sum up, precision metal stamping is an efficient, economical and reliable manufacturing process that can meet the parts production needs of different industries and fields.

Advantages of HY precision metal stamping

We use the most advanced stamping machines, including manual stamping machines, mechanical punching machines, hydraulic punching machines, pneumatic punching machines, high-speed mechanical punching machines, and CNC punching machines, to manufacture high-quality stamping parts accurately, precisely, and on time.

We have experienced engineers and machinists utilizing best-in-class software including SolidWorks, MasterCAM, AutoCAD and Espirit CAM to create 3D CAD models that meet Design for Manufacturing (DFM) standards ᅳ meaning we design parts to be easy to manufacture.

Our nearly 20 years of design and manufacturing experience and quality inspection team can meet the strict requirements of various industries, especially automated automobiles, medical equipment, and the petroleum, aerospace and aviation industries.

We are experts in rapid prototyping. In the early stage of product development, we have small batch stamping and proofing services and can provide you with early product testing.

We have strong quality and environmental systems and our factories are ISO 9001:2015, ISO 14001:2015 and TS16949:2015 certified.

hy’s precision metal stamping materials

Aluminum alloy: L2, L3, LF21, LY12

Steel: SUS303, 304, 316, Q195, Q235, DT1, DT2, Q345 (16Mn), Q295 (09Mn2), 1Cr18Ni9Ti, 1Cr13

Brass: T1, T2, H62, H68

Special alloys: Kovar, Invar, Inconel, titanium, blunt copper, etc.